Product Description

Characteristic advantages

1. Corrosion resistance: Resistant to strong corrosive environments such as seawater, acidity, chloride, etc

2. High tensile strength, suitable for high-pressure or high wear conditions

3. Good wear resistance suitable for filtering abrasive media

4. Long service life, not easily deformed or damaged during long-term use

Common specifications

The commonly used models are

2205(UNS S31803 / S32205)

2507(UNS S32750)

They can replace stainless steel such as 304 and 316 and perform better in corrosive environments

Mesh Count | Wire Diameter (mm / inch) | Aperture Size Approx. (mm / inch) | Weave Type | Typical Applications |

10 mesh | 0.60 mm / 0.0236" | 1.94 mm / 0.0764" | Plain Weave | Particle screening, machine guards |

20 mesh | 0.50 mm / 0.0197" | 0.77 mm / 0.0303" | Plain Weave | Primary filtration of fluids |

40 mesh | 0.28 mm / 0.0110" | 0.36 mm / 0.0142" | Plain Weave | Coarse filtration |

60 mesh | 0.18 mm / 0.0071" | 0.24 mm / 0.0094" | Plain/Twill Weave | Chemical, pharmaceutical filtration |

80 mesh | 0.15 mm / 0.0059" | 0.17 mm / 0.0067" | Plain Weave | Powder filtration |

100 mesh | 0.10 mm / 0.0039" | 0.15 mm / 0.0059" | Plain/Twill Weave | Fine filtration |

150 mesh | 0.07 mm / 0.0028" | 0.10 mm / 0.0039" | Twill Weave | Precision filtration |

200 mesh | 0.05 mm / 0.0020" | 0.08 mm / 0.0031" | Twill Weave | Ultra-fine and gas filtration |

Application Area

1. Marine engineering: such as seawater desalination filters, marine inlet filters

2. Petroleum and natural gas: used for screening, filtering, catalyst support, etc

3. Chemical equipment: reactor internal structure, filter elements

4. Paper, food, and pharmaceutical industries: filtration processes with high requirements for cleanliness and corrosion resistance

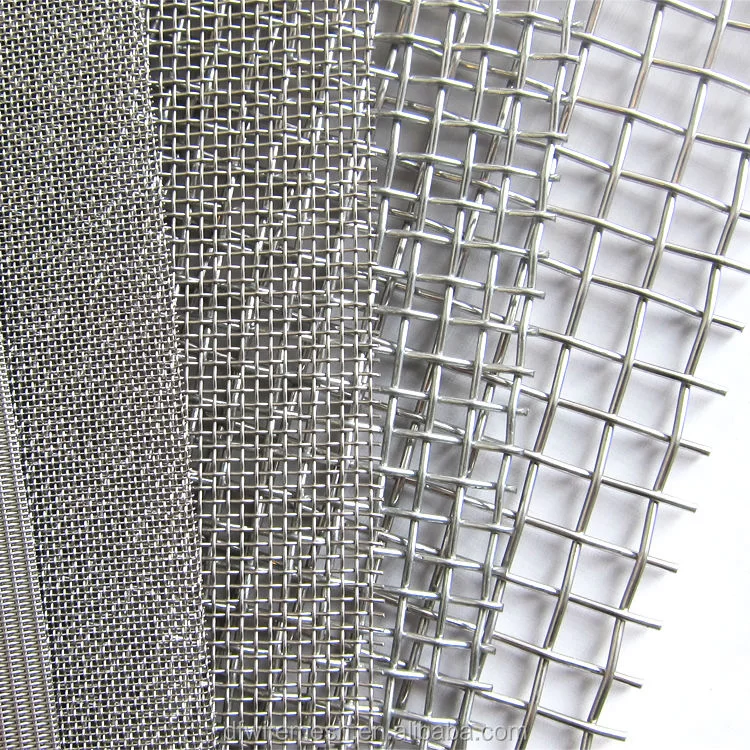

The Duplex Stainless Woven Wire Mesh is a high-performance product designed to meet the rigorous demands of modern industrial applications. Crafted from duplex stainless steel, this metal woven wire mesh offers outstanding corrosion resistance, making it suitable for use in harsh environments, including chemical processing, marine applications, and filtration systems. The duplex stainless steel material combines the best properties of both austenitic and ferritic stainless steels, providing enhanced strength and durability.

This woven wire mesh features a precise weaving pattern that ensures uniform openings and exceptional mechanical stability. It is widely used for filtration, sieving, separation, and protective screening. Its robust construction allows it to withstand high pressure and temperature variations without deforming or losing functionality.

Thanks to its corrosion resistance, the duplex stainless steel mesh is ideal for applications requiring long-term reliability and minimal maintenance. It also provides excellent resistance against stress corrosion cracking, making it a preferred choice in many industrial sectors.

In addition to industrial uses, the metal woven wire mesh is also utilized in architectural projects and protective barriers due to its aesthetic appeal and strength. Available in various mesh sizes and wire diameters, it can be customized to meet specific project requirements.

With strict quality control and advanced manufacturing techniques, our duplex stainless woven wire mesh guarantees consistent quality and performance for all your needs.

Our metal woven wire mesh, made from premium duplex stainless steel, delivers exceptional durability and corrosion resistance, making it ideal for challenging industrial environments. The duplex stainless woven wire mesh offers a perfect balance between strength and corrosion protection, which is critical in applications such as filtration, separation, and reinforcement.

The unique duplex structure consists of a mixed microstructure of austenite and ferrite phases, granting it superior mechanical properties compared to standard stainless steel meshes. This ensures the mesh maintains its integrity under mechanical stress and corrosive conditions, extending its service life and reducing replacement costs.

This woven wire mesh is engineered with precision weaving techniques that create consistent mesh openings and reliable filtration performance. It is widely employed in chemical processing plants, oil and gas industries, water treatment facilities, and architectural projects. The duplex stainless steel composition offers excellent resistance to chloride stress corrosion cracking, acid attacks, and pitting corrosion, which are common challenges in industrial applications.

Additionally, the metal woven wire mesh is versatile in terms of size, wire diameter, and weaving patterns, enabling customization to suit specific filtration or screening requirements. Whether used as a filter medium or a structural reinforcement, this mesh provides reliable performance and structural stability.

Please leave us a message and we will get back to you shortly.