Product Description

Characteristic Advantages

1. High precision: capable of achieving a machining accuracy of ± 0.01mm

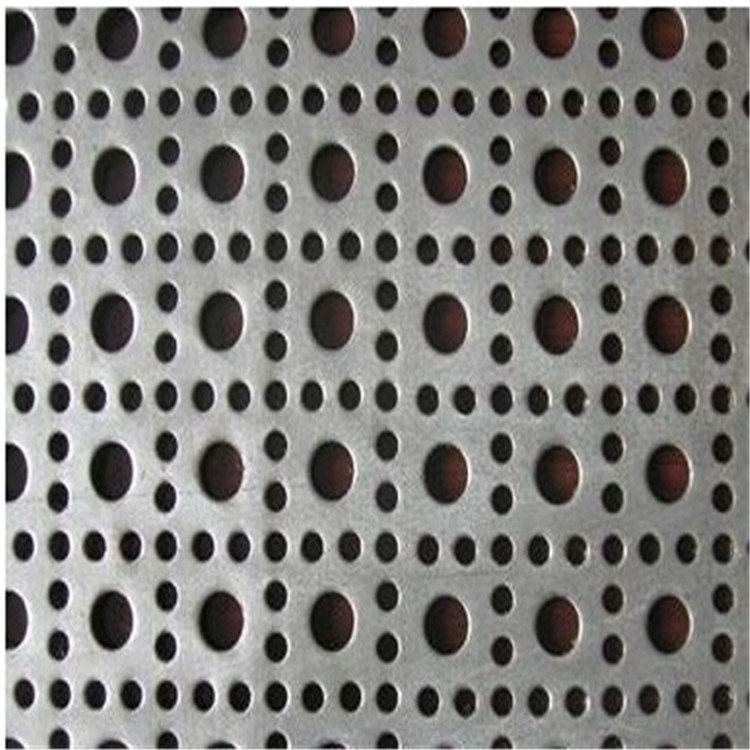

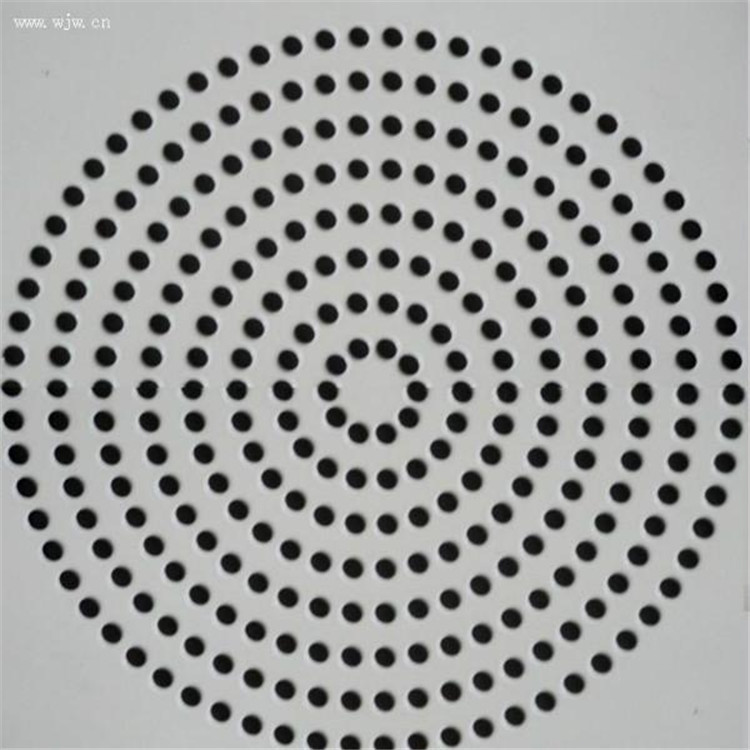

2. Flexible hole type: can be designed with any shape, density, and arrangement

3. Smooth edges: no burrs, no deformation

4. No mechanical stress: does not damage the material structure

5. Mass production: suitable for mass production of products with high consistency

Common Specifications

Parameter Category | Description | Common Range | Example |

Hole Diameter | Diameter of the perforations | 0.5mm – 100mm (Common: 1mm, 2mm, 5mm, 10mm) | Example: 2mm round hole means each hole has a 2mm diameter |

Sheet Thickness | Thickness of the metal sheet | 0.3mm – 10mm (Common: 0.5mm, 1mm, 1.5mm, 2mm, 3mm) | Thicker plates offer more strength but are heavier and harder to process |

Pitch (Center Distance) | Distance between centers of adjacent holes | Typically 1.5 – 3× the hole diameter | Example: 2mm hole, 3mm pitch |

Open Area (Porosity) | Percentage of the total sheet area that is open/perforated | 20% – 80% | Higher open area = better airflow or light transmission |

Hole Arrangement | Hole layout pattern | Straight (90°), Staggered (60°), Horizontal or Vertical arrangement | Staggered layout offers better strength and aesthetics |

Common Hole Shapes | Perforation geometry | Round, Slotted (Oblong), Square, Hexagonal, Diamond, Custom designs | Round holes are the most common |

Standard Sheet Size | Dimensions of a full sheet | Common sizes: 1000×2000mm1220×2440mm1250×2500mm1500×3000mm | Custom sizes or coil supply available on request |

Edge Treatment | Whether edges are deburred or rolled | Clean edge, burr edge, rolled edge | Rolled edges used for safety or design requirements |

Material Type | Base metal materials | Stainless steel, carbon steel, aluminum, copper, titanium, galvanized steel, plastic, etc. | Different materials offer varying levels of corrosion resistance and strength |

Hole Diameter | Pitch (Center Distance) | Thickness | Open Area (Approx.) | Hole Shape | Pattern |

1 | 2 | 0.5 | 23% | Round | 60° staggered |

2 | 3 | 1 | 40% | Round | Straight |

3 | 5 | 1.2 | 33% | Round | 60° staggered |

5 | 8 | 1.5 | 37% | Round | Straight |

10 | 15 | 2 | 40% | Round | Staggered |

0.5×5.0 | 8 | 1 | 32% | Slotted | Straight |

10×10 | 14 | 1.5 | 50% | Square | Straight |

Application Area

Application | Suggested Specification |

Ventilation / Heat Dissipation | Thin sheets, high open area (e.g., 1mm holes, 60% open area) |

Screening / Filtering | Small holes, dense patterns (e.g., 1.5mm staggered holes) |

Machine Guarding | Thicker sheets with larger holes (e.g., 10mm holes, 2mm thick) |

Architectural Decoration | Custom hole designs, balance between aesthetics and strength |

Acoustic Panels | High open area with small round or hexagonal holes |

Our punching and etch filter screen is engineered for fine and uniform filtration in industries requiring high precision and compact design. By integrating punching techniques with advanced chemical etching, this metal mesh filter screen provides exceptional dimensional accuracy, micro-aperture control, and consistent flow characteristics.

Made from filter mesh stainless steel, this screen offers excellent corrosion resistance, high temperature tolerance, and mechanical strength. It is suitable for use in aerospace, fuel systems, medical devices, and chemical processing, where filtration of ultra-fine particles is critical. The etched pattern enables high filtration accuracy, while the punched structure increases mechanical support and permeability.

Compared to woven filters, the wire mesh filter screen in etched form does not shift or fray, ensuring stable performance and longer service life. The combination of micro-perforation and structural etching also minimizes pressure drop and allows for custom designs, making it adaptable to a wide variety of equipment sizes and requirements.

Available in ultra-thin and small metal screen filter formats, this product is ideal for precision-engineered systems. We also offer sintered mesh screen options for high-pressure filtration. Whether you're upgrading your current metal mesh screen filter or designing a new system, this solution ensures reliability and precision.

Our filter mesh stainless steel screen with combined punching and etching is a versatile solution for both coarse and micro-filtration. By utilizing advanced punching and etch filter screen technology, we deliver products with ultra-fine precision, making them ideal for sensitive filtration tasks in compact or high-performance systems.

This metal mesh screen filter is manufactured from high-quality stainless steel, ensuring corrosion resistance, thermal stability, and structural integrity under harsh conditions. Unlike standard woven wire mesh, the etched apertures offer consistent flow paths and eliminate fraying or shifting, while the punched holes provide structural reinforcement and enhanced flow rates.

Commonly used in fuel injectors, air diffusers, microelectronics, and filtration devices, the small metal screen filter ensures high-accuracy performance even in limited space. Whether used for liquid, air, or gas filtration, it maintains efficiency and stability across extended cycles.

For added durability and multi-layer protection, we offer options like sintered mesh screen structures—especially suited for high-pressure or high-temperature systems. The etched-punched hybrid screen can be fabricated in flat sheets, discs, tubes, or custom profiles, making it adaptable to a wide range of applications.

Our wire mesh filter screen technology delivers the advantages of precise slot control, minimal clogging, and reduced maintenance. Choose our punching and etch filter screen for a next-generation filtration solution that combines precision, strength, and versatility in one compact design.

Please leave us a message and we will get back to you shortly.