Product Description

Characteristic Advantages

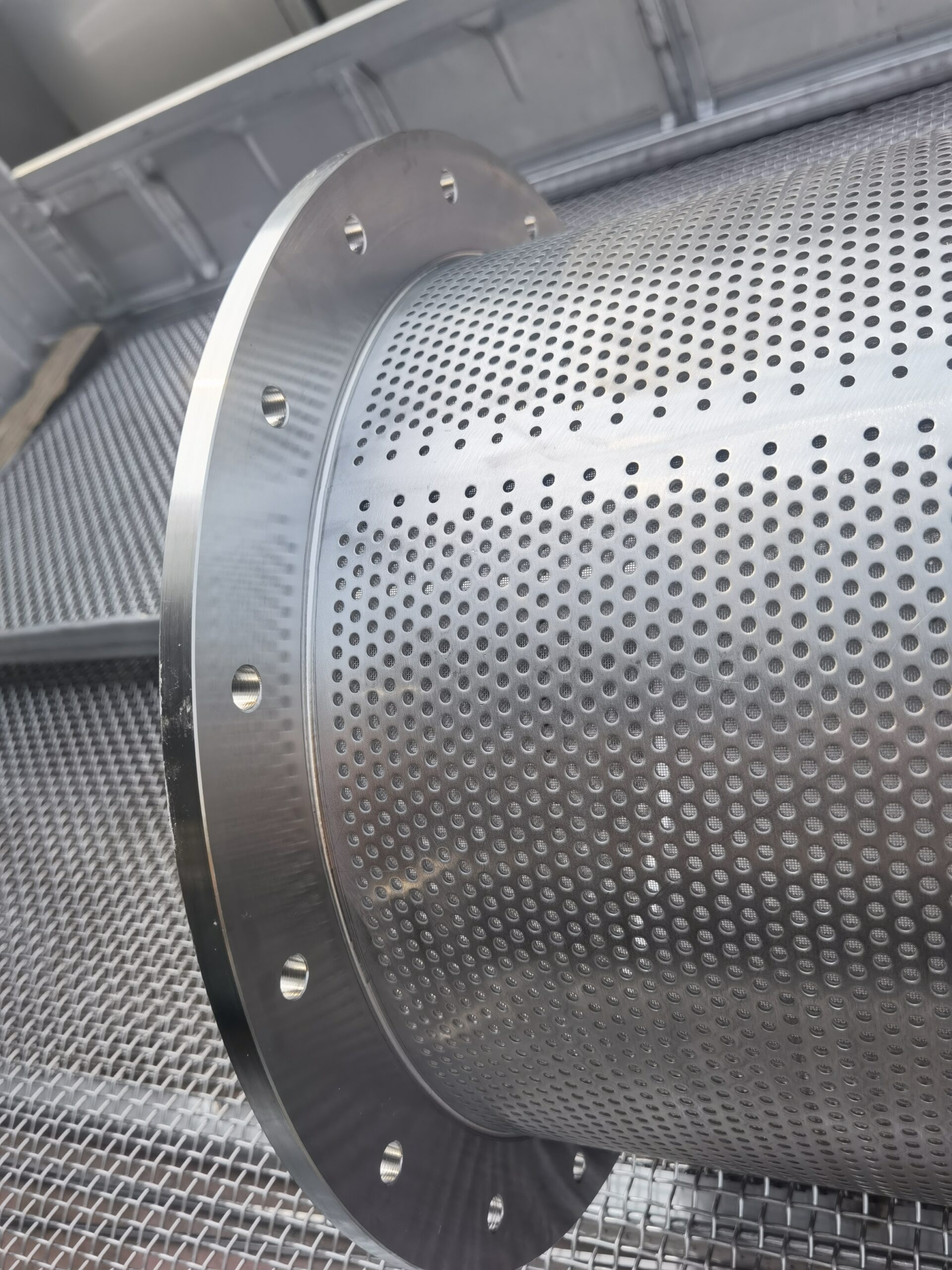

1. High strength and strong compression resistance: suitable for high-pressure and high flow rate environments;

2. Diverse pore sizes and good permeability: can accurately control pore size and opening rate;

3. Stable structure and not easily deformed: suitable for repeated cleaning and long-term use;

4. Can be used in combination with woven mesh and sintered mesh to improve filtration efficiency;

5. Support multiple welding and connection methods: adapt to different working conditions and interface requirements

Common Specifications

Perforation Types

Circular hole (most common)

Elliptical hole

Longhole (elongated hole, slotted hole)

square hole

Customized shapes such as hexagonal holes and bridge holes

Parameter | Typical Values / Options |

Material | SS304, SS316, SS316L, Carbon Steel, Aluminum, Titanium |

Tube Diameter (OD) | 20 mm – 300 mm |

Length | 50 mm – 1200 mm |

Thickness of Plate | 0.3 mm – 2.0 mm (standard: 0.5–1.5 mm) |

Hole Diameter | 0.5 mm – 10 mm |

Hole Pattern | Round, slot, square, staggered or straight pitch |

Open Area (Porosity) | 10% – 60% |

Support Structure | Optional inner or outer mesh (woven/sintered) |

End Types | Flat, threaded, flanged, closed-end, custom |

Connection Methods | Argon arc welding, spot welding, laser welding, bonding |

Working Temperature | Up to 600°C (material dependent) |

Working Pressure | Up to 5 MPa or more (depending on thickness and structure) |

Cleaning Methods | Ultrasonic, backflush, solvent cleaning |

Application Area

1. Petrochemical filtration (crude oil, water, gas filtration)

2. Pre filtration of water treatment system

3. Particle interception in the food and beverage industry

4. Filter housing for agricultural irrigation system

5. Protection and filtration of hydraulic oil and lubricating oil systems

6. Pre filtration of medical equipment and sterilization devices

7. Dust removal and interception of powder conveying system

The perforated metal filter tube is a reliable and versatile filtration component designed to withstand pressure, corrosion, and heavy-duty flow. Made from stainless steel or aluminum, this metal filter tube is precision-perforated to allow fluid or air to pass through while retaining unwanted solids, making it ideal for applications in filtration, drainage, air ventilation, and oil separation.

With customizable hole patterns, diameters, and wall thicknesses, our filter tubes can be tailored to specific performance needs. The perforated aluminium tube offers lightweight corrosion resistance, making it suitable for marine or humid environments, while perforated aluminum square tubing provides structural support and modern aesthetics for architectural and HVAC applications.

In wastewater systems, the perforated corrugated drain pipe variant of this product is widely used for underground water redirection, offering flexibility and long service life. Our filter tubes are also compatible with filtration media, making them effective as cartridge cores or structural reinforcements in layered filtration systems.

Whether you need a metal square tube with holes for structural drainage or a compact perforated aluminum tube for air control, this product line offers functionality, ease of fabrication, and resilience. Perfect for industrial, architectural, and environmental applications, our metal filter tube ensures long-lasting performance with minimal maintenance.

Our perforated aluminum tube is a high-performance solution for applications requiring lightweight construction, corrosion resistance, and precise fluid control. This perforated metal filter tube is fabricated from high-quality aluminum and features evenly distributed holes that provide uniform airflow or fluid passage while blocking debris and contaminants.

Ideal for use in air filtration systems, exhaust components, water filtration, and structural ventilation, this tube can be customized in length, diameter, perforation pattern, and hole size. The perforated aluminum square tubing variant offers both strength and a modern appearance, making it suitable for architectural facades, sunscreens, and HVAC structures.

When used in subsurface applications, such as water management or agricultural drainage, the perforated corrugated drain pipe option provides flexibility and resistance to deformation under soil pressure. Its open-area design promotes quick drainage, reducing water buildup and soil saturation.

The metal square tube with holes option serves a dual purpose in both functional and decorative applications, offering strength and filtration in one. These tubes can be layered with filter media or used alone as structural filter components. Their ease of fabrication allows them to be cut, welded, or fitted to match any system requirements.

Whether you're designing a filtration unit, water drainage system, or architectural installation, our metal filter tube product range—including perforated aluminium tubes—delivers reliable, efficient, and sustainable performance across all sectors.

Please leave us a message and we will get back to you shortly.