Product Description

Characteristic Advantages

1. High strength and impact resistance: Suitable for high-pressure and pulsed fluids through internal and external support and multi-layer compression;

2. Stable filtering accuracy: The multi-layer woven mesh structure ensures uniform pore size distribution and long-term stable accuracy;

3. High pollutant absorption capacity: Folding or multi-layer arrangement gives it a larger effective filtering area;

4. High temperature and corrosion resistance: Special alloys such as stainless steel, Inconel, Hastelloy, etc. can be selected;

5. Can be blown back and cleaned for reuse: supports ultrasonic, reverse flushing, chemical cleaning and other methods;

6. Diversified structure: straight tube type, folding type, bottom sealing type, flange connection type, and other optional types

Common Specifications

Manufacturing Process

1. Selected metal wire woven mesh materials

2. Accurately crop according to hierarchy

3. Align and overlap layers to form a composite structure

4. Edge welding or high-temperature sintering forming (optional)

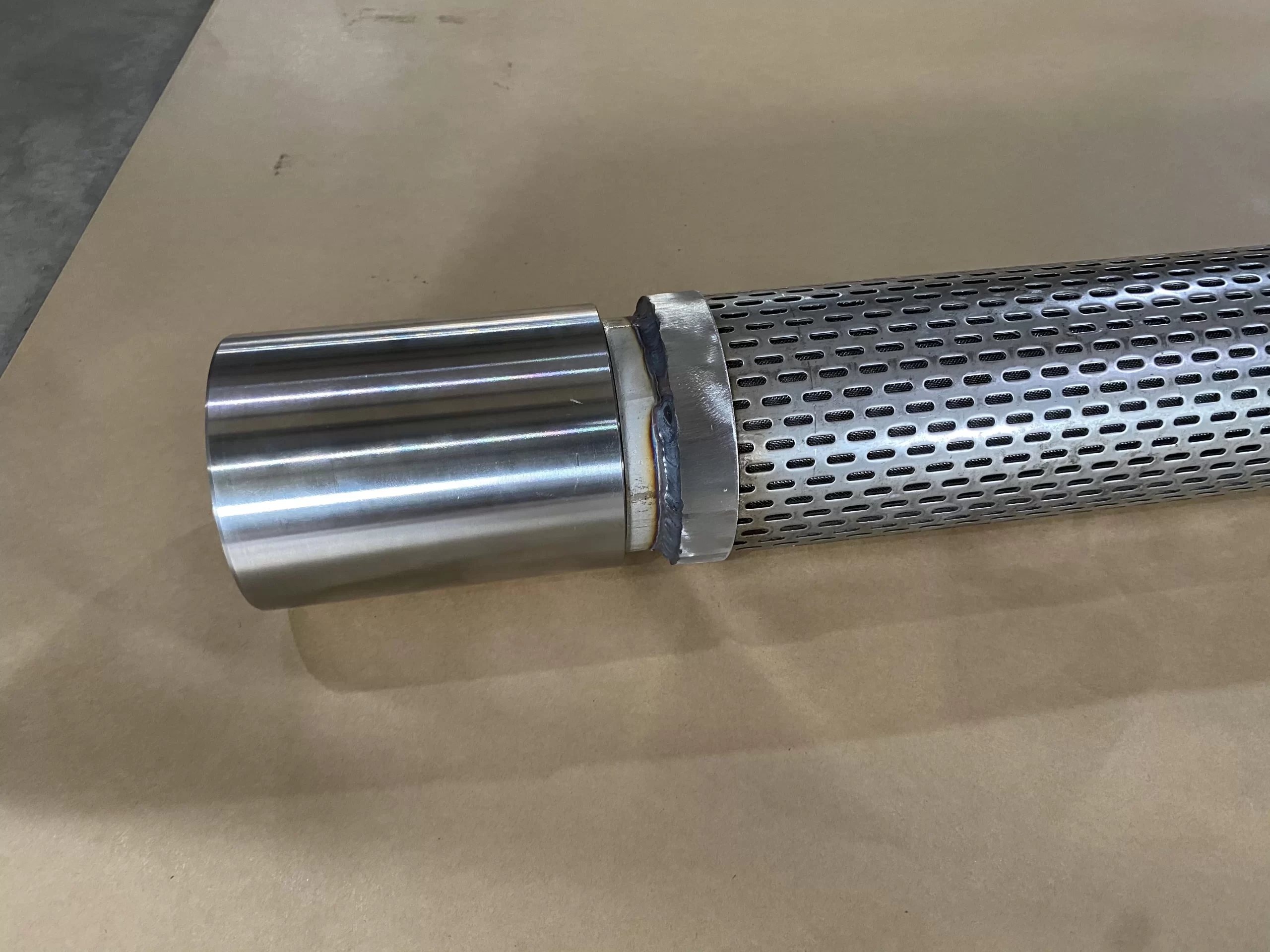

5. Internal support tube assembly (if required)

6. Two end interface processing: welding flanges, threads, seals, etc

7. Leak detection, pressure testing, and packaging cleaning

The filter tube usually consists of 3 to 5 functional mesh layers, each serving a specific role:

Layer | Function | Typical Mesh Size |

Outer Protective Layer | Prevents mechanical damage from outside forces | 10–40 mesh |

Filtration Layer | Primary fine filtration to trap particles | 80–400 mesh |

Distribution Layer | Promotes uniform flow distribution and reduces clogging | 40–80 mesh |

Support Layer | Provides mechanical strength and pressure resistance | 20–50 mesh or perforated metal |

Inner Layer (Optional) | Prevents back-pressure damage or inward collapse | 10–30 mesh |

Layer combinations, mesh sizes, and arrangement can be customized for specific operating conditions.

Material | SS304, SS316L, Inconel, Monel, Hastelloy, Titanium |

Outer Diameter (OD) | 20 mm – 150 mm |

Length | 50 mm – 1000 mm (custom sizes available) |

Number of Layers | 3 – 5 layers (up to 7 layers on request) |

Mesh Size Range | 10 – 500 mesh (commonly 40–300 mesh combinations) |

Filtration Rating | 1 – 200 μm (standard options: 5, 10, 25, 50, 75, 100 μm) |

Operating Temperature | -200°C to +600°C (material-dependent) |

Operating Pressure | 1 – 6 MPa (up to 30 MPa with reinforced design) |

End Connection Options | Threaded (NPT/BSP), flanged, welded, quick-connect, push-fit |

Cleaning Methods | Ultrasonic, backflushing, solvent soaking, hot air blowing |

Surface Finish | Pickled, passivated, polished |

Application Area

1.Fine chemical filtration (acids, resins, polymers)

2.Hydraulic & lubrication oil filtration

3.Pharmaceutical-grade sterile air or liquid filtration

4.Ultrafiltration or RO pre-filtration in water systems

5.Food-grade syrup, starch, or viscous liquid filtration

6.Aerospace and nuclear power high-spec filter systems

Our multi-layer composite woven wire mesh filter tube is a highly efficient stainless steel mesh filter designed for both liquid and gas filtration in demanding industrial environments. It features multiple layers of precision-woven stainless mesh filter material, sintered or spot-welded together to create a robust and durable filtration unit.

This stainless steel mesh filter element provides uniform pore size distribution and high mechanical strength, making it ideal for high-pressure or high-temperature systems. Whether used in hydraulic systems, petrochemical processes, or gas filtration setups, it ensures consistent filtration performance while resisting corrosion and deformation.

The tube design maximizes surface area and structural support, allowing for extended service life and reduced maintenance frequency. It can be cleaned and reused multiple times, making it a cost-effective and sustainable alternative to disposable filters.

Additionally, this filter tube can be manufactured with stainless steel wedge wire screen for applications requiring slot-style filtration, or with stainless steel mesh air filter materials for HVAC or ventilation purposes. Available in various micron ratings, diameters, and lengths, it can be tailored to meet specific filtration needs.

Engineered for precision, strength, and longevity, our stainless steel mesh filter tubes are the go-to solution for reliable and efficient industrial filtration.

The multi-layer composite woven wire mesh filter tube is a high-performance stainless mesh filter solution built to withstand harsh operational conditions. Designed with multiple layers of woven mesh, it achieves excellent strength, rigidity, and filtration accuracy, making it suitable for use in oil, gas, chemical, and air purification systems.

This stainless steel mesh filter features an advanced sintered or welded construction, combining various mesh layers into a rigid, unified structure. The filter can be customized in terms of mesh count, tube diameter, and wall thickness, allowing for exact alignment with your process needs.

In addition to liquid filtration, the product also functions efficiently as a stainless steel mesh air filter, capturing fine airborne particles in HVAC systems and industrial ventilation setups. Its corrosion-resistant stainless steel material makes it ideal for long-term exposure to high temperatures, chemicals, or moisture-rich environments.

The stainless steel wedge wire screen option is also available for coarse filtration or separation applications, providing directional flow and self-cleaning capabilities. Whether you're filtering particles from fuel, compressed air, solvents, or processing fluids, this stainless steel mesh filter element ensures long-lasting, reliable performance.

Reusable, cleanable, and environmentally friendly, this filter tube offers both economic and operational advantages. Choose our multi-layer stainless steel mesh filter tube for a filtration solution that combines engineering precision with industrial toughness.

Please leave us a message and we will get back to you shortly.