Product Description

Characteristic Advantages

1. Strong corrosion resistance, stable to seawater, acidic and alkaline solutions, chlorides, nitric acid, aqua regia, etc

2. Lightweight, high strength, and density are about 60% of stainless steel, with a higher specific strength than most metals

Although not as good as copper in terms of thermal and electrical conductivity, it meets most engineering requirements

4. Non magnetic is suitable for applications such as medical and electronic industries that require non-magnetic properties

5. Good biocompatibility for medical implantation and fluid contact environments

6 can be used at high temperatures with a melting point of about 1660 ° C and a working temperature of up to 600 ° C+

Common Specifications

Grade | Material Type | Key Characteristics | Typical Applications |

Grade 1 | Commercially Pure Titanium (CP Ti) | Softest and most ductile; excellent corrosion resistance; high formability | Chemical processing, marine components, medical instruments |

Grade 2 | Commercially Pure Titanium (CP Ti) | Most widely used grade; good strength-to-weight ratio; excellent corrosion resistance | Heat exchangers, pressure vessels, desalination, architectural mesh |

Grade 3 | Commercially Pure Titanium (CP Ti) | Higher strength than Grades 1 & 2; slightly lower ductility | Aerospace structures, chemical tanks, piping systems |

Grade 4 | Commercially Pure Titanium (CP Ti) | Highest strength among CP grades; excellent corrosion resistance | Aircraft components, surgical hardware, marine environments |

Grade 5 | Titanium Alloy (Ti-6Al-4V) | Most commonly used alloy; very high strength; good weldability; high temperature service | Aerospace, medical implants, racing, industrial fasteners |

Mesh Count(Number of eyes) | Wire Diameter (mm / inch) | Aperture Size (mm / inch) | Open Area (%) | Weave Type | Typical Applications |

4 × 4 | 1.00 mm / 0.0394" | 5.35 mm / 0.2106" | ~74% | Plain Weave | Marine cage mesh, heavy-duty filter |

10 × 10 | 0.60 mm / 0.0236" | 1.94 mm / 0.0764" | ~60% | Plain Weave | Anode mesh, seawater filtration |

16 × 16 | 0.40 mm / 0.0157" | 1.19 mm / 0.0468" | ~57% | Plain Weave | Chlor-alkali electrolysis |

20 × 20 | 0.35 mm / 0.0138" | 0.92 mm / 0.0362" | ~51% | Plain / Twill | Electrochemical filter, battery separator |

40 × 40 | 0.20 mm / 0.0079" | 0.43 mm / 0.0169" | ~44% | Twill Weave | Fine filtration, catalyst carrier |

60 × 60 | 0.15 mm / 0.0059" | 0.27 mm / 0.0106" | ~40% | Twill Weave | Electroplating support mesh |

80 × 80 | 0.12 mm / 0.0047" | 0.20 mm / 0.0079" | ~36% | Dutch Weave | Gas diffusion layer, precision filtration |

100 × 100 | 0.10 mm / 0.0039" | 0.15 mm / 0.0059" | ~30% | Dutch Weave | Fuel cell component, microfiltration |

150 × 150 | 0.07 mm / 0.0028" | 0.10 mm / 0.0039" | ~28% | Dutch Weave | High purity chemical filtration |

200 × 200 | 0.05 mm / 0.0020" | 0.077 mm / 0.0030" | ~25% | Reverse Dutch | Semiconductor liquid filter, ultrafiltration |

Application Area

Application Field | Description / Usage |

Marine Engineering / Shipbuilding | Resistant to seawater corrosion; used in ship window screens, anti-fouling nets, marine filters |

Chemical Processing / Acid-Alkali Systems | Ideal for corrosive environments; used as acid-washing mesh, filtration mesh, or electrochemical mesh |

Electroplating & Electrolysis | Commonly used as anode/cathode mesh or conductive support mesh in electrolytic processes |

Aerospace Industry | Lightweight and strong; used in fuel system filters, reinforcement mesh, or shielding layers |

Medical & Biomedical Applications | Excellent biocompatibility; used for surgical mesh, bone scaffolds, and implant filters |

Nuclear & Power Generation | High temperature and corrosion resistance; used in heat exchangers, nuclear reactor shielding |

Environmental Filtration Equipment | Applied in gas filtration, wastewater treatment, and as catalyst support mesh |

Desalination / Water Treatment | Used in pre-filtration for reverse osmosis, electrolysis electrodes, and corrosion-resistant barriers |

Fuel Cells & Hydrogen Industry | Serves as gas diffusion layers (GDL), current collectors, and electrode supports |

Laboratory & Scientific Equipment | High corrosion resistance; ideal for sieving, filtration, and controlled environment tests |

Precision Electronics / Semiconductors | Used in cleanroom filters, sputtering target protection, and static-resistant shielding |

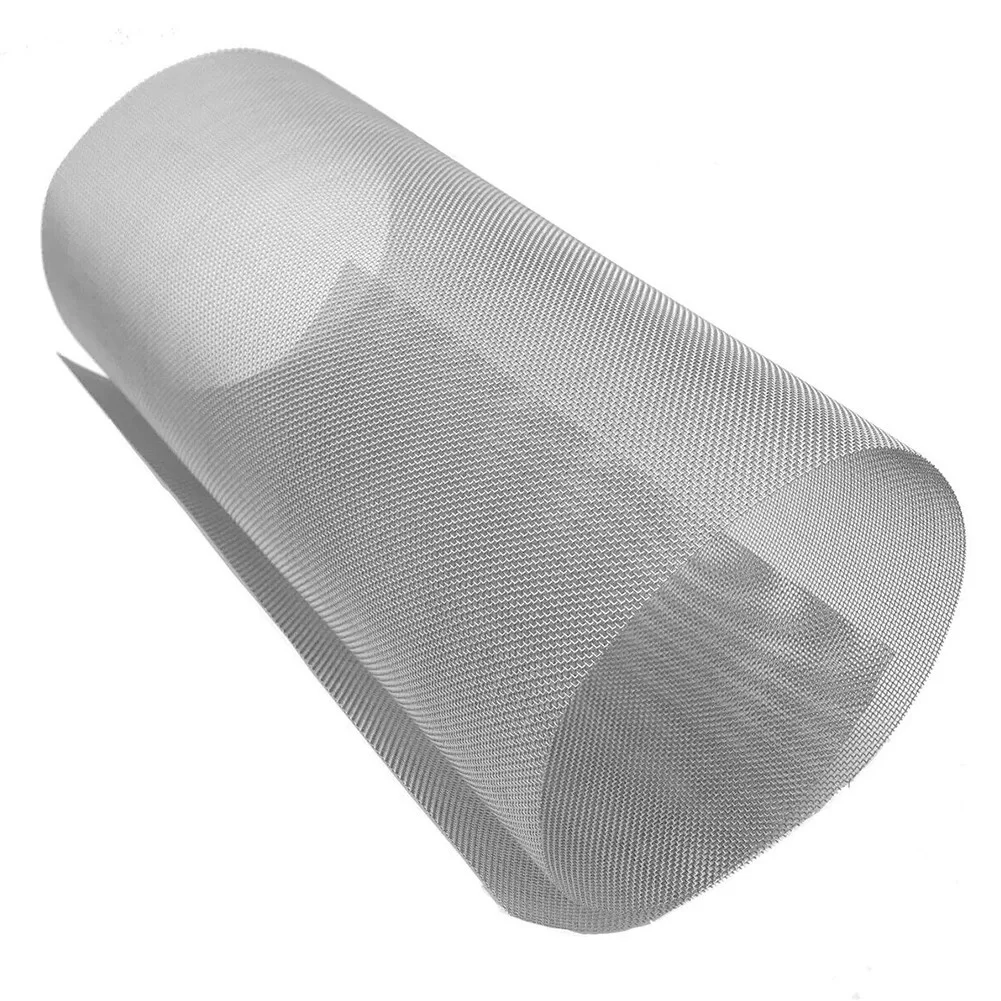

Titanium woven wire mesh is a premium filtration and separation material known for its excellent resistance to corrosion, especially in chloride-rich or acidic environments. Thanks to its light weight and high tensile strength, it is widely used in industries like aerospace, chemical processing, medical filtration, and marine engineering. This mesh maintains structural integrity under extreme heat and pressure, making it ideal for harsh industrial settings.

Additionally, titanium woven wire mesh provides a long service life, reducing the need for frequent replacements and maintenance. It is non-magnetic, non-toxic, and biocompatible, which also makes it suitable for applications in the food, pharmaceutical, and medical industries. Available in a variety of mesh sizes and weave patterns, this mesh can be customized to meet specific functional requirements such as precise filtration or shielding.

Designed for high-demand environments, titanium woven wire mesh delivers unmatched performance in corrosion-prone, high-stress applications. It offers excellent resistance to seawater, acids, and alkalis, making it perfect for desalination plants, marine filters, and battery separators.

The mesh is also widely used in industries requiring long-lasting filtration components with low weight and high strength, such as aviation, automotive, and clean energy. Its thermal and chemical stability ensures that the mesh retains shape and function even under repeated exposure to heat and reactive agents. With precise manufacturing techniques, titanium woven wire mesh is available in ultra-fine to coarse grades, supporting everything from microfiltration to structural reinforcement.

Please leave us a message and we will get back to you shortly.