Stainless steel woven wire mesh is an indispensable material across a myriad of industrial sectors, recognized for its superior performance characteristics. This versatile product is meticulously manufactured by weaving high-quality stainless steel wires to form precise square or oblong openings. The inherent properties of stainless steel, such as exceptional resistance to rust, corrosion, acids, alkalis, heat, and a wide range of chemicals, are directly imparted to the mesh. This robust construction ensures high strength, remarkable durability, and extended service life, making it a preferred choice over conventional materials in demanding environments. Its extensive applications span from intricate filtration systems in petrochemical processes to architectural enhancements and critical components in water treatment facilities, showcasing its adaptability and reliability in diverse settings.

The market for industrial filtration and separation technologies is continuously evolving, driven by stringent environmental regulations and the escalating need for process optimization. Industry trends highlight a growing demand for advanced materials like dutch woven wire mesh and specialized alloys such as stainless steel 904L sheets. These materials offer enhanced performance in extreme conditions, contributing significantly to operational efficiency and product purity. The shift towards sustainable manufacturing practices also emphasizes materials with extended lifespan and recyclability, where stainless steel products, including various grades of steel woven mesh, consistently outperform alternatives. Emerging applications in renewable energy and high-tech manufacturing further underscore the critical role of these advanced metallic solutions in shaping future industrial landscapes.

The production of dutch woven wire mesh involves a highly specialized weaving technique designed to create a robust and dense fabric with superior filtration capabilities. The process begins with selecting premium-grade stainless steel wire, typically 304, 316, or specialized alloys like 904L, drawn to precise diameters. Unlike plain or twill weaves, dutch weave uses different wire diameters and mesh counts for warp and weft wires. Finer weft wires are driven closer together, creating a conical opening that offers high flow rates and exceptional particle retention, making it ideal for critical filtration applications in petrochemical, pharmaceutical, and food processing industries. Each stage, from wire drawing to annealing and weaving, is controlled to meet stringent quality standards like ASTM E2016 for industrial wire cloth.

The creation of stainless steel 904L sheets is a testament to advanced metallurgical engineering. This process typically starts with melting high-purity raw materials in an electric arc furnace, followed by refining in a ladle furnace to control alloy composition rigorously. The molten metal is then cast into slabs, which undergo hot rolling at temperatures exceeding 1000°C to reduce thickness and refine grain structure. Subsequent cold rolling further enhances surface finish and mechanical properties. A critical step is solution annealing, where sheets are heated to over 1050°C and rapidly cooled to optimize corrosion resistance and ductility. Each sheet is subjected to rigorous quality checks, including ultrasonic testing for internal defects and compliance with international standards such as ASTM A240 for pressure vessels. This meticulous process ensures the longevity and performance of 904L sheets in highly corrosive environments, such as sulfuric acid plants and marine applications.

General steel woven mesh, encompassing various weave types like plain, twill, and crimped, is produced through a continuous weaving process. High-speed looms interlace warp and weft wires to create a stable, uniform mesh. The choice of material—whether stainless steel (304, 316, 310, 904L) or other alloys—dictates the mesh's ultimate properties. Post-weaving, the mesh may undergo secondary processes such as calendering for specific thickness or surface finishes, and ultrasonic cleaning to remove any processing residues. Inspection protocols adhering to ISO 9001 and internal quality management systems ensure consistent aperture size, wire diameter, and tensile strength. The adaptability of steel woven mesh makes it suitable for diverse applications, from aggregate screening in mining to pest control and architectural infill panels, offering cost-effectiveness and durability.

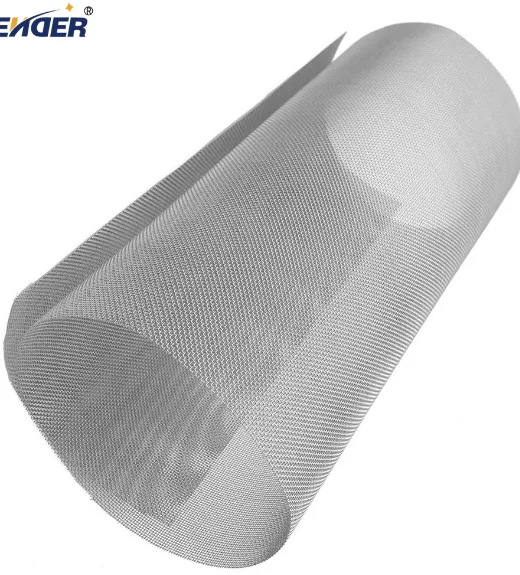

The above image conceptually illustrates the intricate weaving process involved in producing high-quality wire mesh. This advanced manufacturing capability ensures that each strand is perfectly positioned, guaranteeing the structural integrity and optimal performance of the final product. Key process parameters include wire tension control, precise loom calibration, and continuous quality monitoring, all aimed at achieving uniform mesh openings and exceptional durability. Our adherence to international manufacturing standards, including ISO 9001:2015, underpins our commitment to delivering products that consistently meet the most stringent industrial demands. This meticulous attention to detail is paramount for applications where precision and reliability are non-negotiable, such as in ultra-fine filtration for sensitive chemical processes.

Selecting the appropriate material is crucial for optimal performance in industrial applications. Below is a comparative table highlighting key technical parameters for dutch woven wire mesh, stainless steel 904L sheets, and general steel woven mesh, demonstrating their distinct strengths and applications. These specifications are critical for engineers and procurement specialists to determine the most cost-effective and functionally superior solution for their unique operational requirements.

Feature/Product | Dutch Woven Wire Mesh | Stainless Steel 904L Sheets | General Steel Woven Mesh |

Primary Application | Fine filtration, high-pressure separation | Extreme corrosion resistance, high-temperature service | Screening, guarding, general filtration |

Material Grades | SS304, SS316, SS316L, Duplex, 904L | UNS N08904 (1.4539) | SS304, SS316, Galvanized, Carbon Steel |

Weave Type | Plain Dutch, Twill Dutch, Reverse Dutch | Solid sheet (rolled, annealed) | Plain, Twill, Crimped, Lock Crimp |

Micron Rating (Typical) | 2 to 200 microns (absolute) | N/A (solid material) | 500 microns to 10 mm (nominal) |

Corrosion Resistance | Excellent (grade-dependent) | Superior (to most SS grades, esp. in sulfuric acid) | Good (grade-dependent) |

Temperature Rating | Up to 800°C (depending on grade) | Up to 450°C (continuous service) | Up to 700°C (depending on grade) |

This comparison illustrates that while general steel woven mesh offers broad utility, dutch woven wire mesh excels in precision filtration, and stainless steel 904L sheets provide unparalleled resistance in extremely aggressive chemical environments. The specific composition of 904L, with higher chromium, nickel, molybdenum, and copper, makes it a super austenitic stainless steel perfectly suited for industries handling sulfuric and phosphoric acids.

To further enhance understanding of Stainless Steel Woven Wire Mesh capabilities, we present a conceptual visualization of its technical indicators. While specific data points vary by application and grade, these charts highlight the typical distribution of key performance attributes that define the reliability and effectiveness of our products.

Key Strengths

· ● Corrosion Resistance (35%)

· ● High Strength & Durability (30%)

· ● Precision Filtration (20%)

· ● Thermal & Chemical Stability (15%)

MildModerateHarshExtreme

Bar chart representing service life under varying environmental conditions.

These graphical representations underscore the multi-faceted advantages of Stainless Steel Woven Wire Mesh, from its inherent material properties contributing to unparalleled corrosion resistance and strength, to its predictable service life across a spectrum of operational demands. Such data empowers B2B clients to make informed decisions, optimizing their investments in filtration and separation technologies while adhering to strict safety and efficiency standards. Our commitment to robust engineering and quality control ensures that these performance metrics are consistently met or exceeded in real-world applications.

The versatility of stainless steel woven wire mesh facilitates its extensive use across numerous high-stakes industrial applications. In the petrochemical industry, fine dutch woven wire mesh serves as a critical component in catalyst retention, molecular sieves, and gas-liquid separation, ensuring process purity and preventing costly downtime. For chemical processing, particularly where aggressive acids are present, filters made from 904L alloy mesh are indispensable. The food and beverage sector relies on hygienic stainless steel mesh for sieving, drying, and washing processes, meeting strict FDA compliance requirements. Furthermore, steel woven mesh is widely employed in mining for aggregate screening, in architectural designs for aesthetic and functional facades, and in water treatment facilities for efficient particle removal. Each application leverages the mesh's specific properties—be it corrosion resistance, thermal stability, or mechanical strength—to enhance operational performance and longevity.

Consider a typical application case in a large-scale wastewater treatment plant, where robust filtration is paramount. Our custom-fabricated stainless steel woven wire mesh panels, utilizing SS316L, were implemented as primary screens to remove coarse solids before subsequent treatment stages. The mesh's inherent corrosion resistance to various chemicals present in wastewater significantly extended the service life of the filtration units, reducing maintenance costs by 30% annually compared to previous systems. Moreover, the precise and uniform openings ensured consistent effluent quality, helping the plant meet stringent environmental discharge regulations. This practical demonstration of durability and efficiency highlights the tangible benefits our engineered mesh solutions deliver to critical infrastructure projects, providing long-term value and operational reliability.

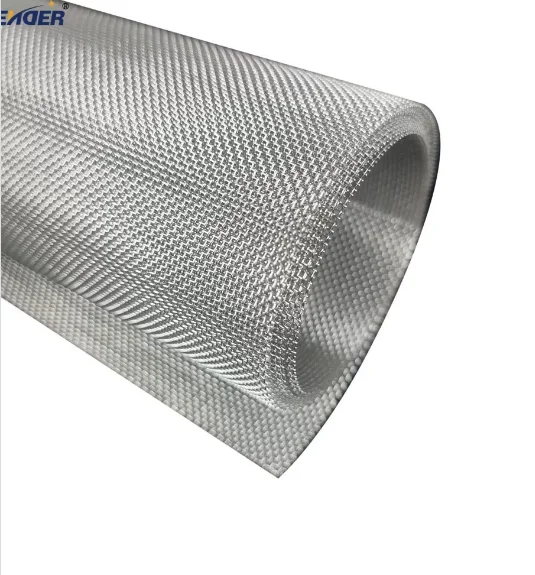

The image above depicts a high-performance steel woven mesh panel integrated into an industrial setup, illustrating a typical application where robust material is essential. Such mesh is often custom-engineered for specific mechanical load-bearing and filtration efficiency requirements. Our engineering team collaborates closely with clients to understand their precise needs, offering bespoke solutions that go beyond standard products. From tailored dimensions and specialized edge treatments to multi-layer composite meshes for enhanced performance, our customization capabilities ensure optimal fit and function for even the most unique industrial challenges. This approach guarantees that the mesh not only performs its primary function effectively but also integrates seamlessly into existing systems, maximizing operational uptime and overall system integrity.

As a leading manufacturer, we pride ourselves on delivering bespoke steel woven mesh and dutch woven wire mesh solutions tailored to the precise needs of our B2B clients. Our expertise extends beyond standard product offerings to include custom fabrication, such as specialized cuts, forms, and finishes. For instance, in an application requiring filtration of highly viscous liquids, we successfully engineered a multi-layered dutch woven mesh filter, combining different micron ratings to achieve progressive filtration efficiency and extended operational cycles. Our in-house design and engineering teams leverage advanced simulation tools to predict performance and optimize designs, ensuring that even the most complex specifications are met with precision. This commitment to customization, backed by decades of industry experience, allows us to address unique challenges with innovative and highly effective solutions.

Our position as an authoritative supplier in the stainless steel mesh industry is founded on an unwavering commitment to quality and transparency. We hold rigorous certifications, including ISO 9001:2015 for quality management, ensuring that every batch of dutch woven wire mesh and stainless steel 904L sheets meets international benchmarks. Our products regularly undergo third-party testing to ASTM and ASME standards, validating their mechanical properties and corrosion resistance. Strategic partnerships with leading material suppliers and over two decades of dedicated service within the petrochemical and water treatment sectors further cement our reputation. We provide comprehensive material test reports (MTRs) with every order, detailing chemical composition, physical properties, and compliance, offering our clients complete assurance in the quality and performance of their purchase.

· 1. What is the primary advantage of Dutch woven wire mesh over plain woven mesh?

Dutch woven mesh offers significantly finer filtration and higher particle retention due to its unique weave pattern, where larger warp wires support tightly packed smaller weft wires. This creates a tortuous path for particles, leading to superior filtration efficiency for critical applications.

·

· 2. In which environments does Stainless Steel 904L Sheets excel?

Stainless Steel 904L is specifically designed for highly corrosive environments, particularly those involving sulfuric acid, phosphoric acid, and seawater. Its high molybdenum and copper content provide excellent resistance to pitting and crevice corrosion, making it superior to standard austenitic steels in such aggressive media.

·

· 3. How is the mesh count or micron rating determined for steel woven mesh?

Mesh count refers to the number of openings per linear inch. Micron rating, for finer meshes like Dutch weave, represents the absolute or nominal particle size that the mesh can retain. Both are critical specifications determined by wire diameter and weaving density, ensuring precise filtration capabilities.

·

· 4. Can your stainless steel woven wire mesh withstand high temperatures?

Yes, depending on the specific stainless steel grade. Grades like 310S are excellent for high-temperature applications up to 1050°C, while 304 and 316 can withstand temperatures up to 870°C. We match the appropriate grade to your thermal requirements.

·

· 5. What are the typical lead times for custom stainless steel woven mesh orders?

Our standard lead time for custom orders of steel woven mesh and dutch woven wire mesh typically ranges from 3 to 6 weeks, depending on the complexity of the design, material availability, and order volume. Expedited services are available for urgent projects.

·

· 6. Do you offer certification and quality assurance for your products?

Absolutely. All our products are supplied with Material Test Certificates (MTCs) compliant with EN 10204 3.1 or 3.2. We ensure full traceability from raw material to finished product and adhere to strict ISO 9001 quality management systems.

·

· 7. What kind of warranty do you provide for stainless steel woven wire mesh?

We offer a comprehensive warranty against manufacturing defects and material failures under normal operating conditions for a period of 12 months from the date of delivery. Our commitment extends to providing robust customer support and technical assistance throughout the product's lifecycle.

·

Our dedicated customer support team is always available to assist with technical queries, order tracking, and post-sales support, ensuring a seamless experience for our valued partners. We stand by the quality and performance of our stainless steel woven wire mesh products, offering a transparent delivery cycle and robust warranty commitments to foster enduring trust.

1. American Society for Testing and Materials (ASTM) Standards for Woven Wire Test Sieve Cloth and Industrial Woven Wire Fabrics.

2. International Organization for Standardization (ISO) 9001:2015 Quality Management Systems – Requirements.

3. The European Standard EN 10204: Inspection Documents for Metallic Products.

4. ASM Handbook, Volume 1: Properties and Selection: Irons, Steels, and High-Performance Alloys.

5. "Corrosion Resistance of Stainless Steels" by A.J. Sedriks, Wiley Interscience.

Contact Information

Quick Link

Product

copyright

Please leave us a message and we will get back to you shortly.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.