In today's demanding industrial environment, the selection of advanced materials is paramount for operational efficiency, safety, and longevity. Industries from petrochemicals to pharmaceuticals increasingly rely on specialized solutions like dutch woven wire mesh, high-grade stainless steel 904l sheets, and robust steel woven mesh to meet stringent performance requirements. These materials are engineered to withstand extreme conditions, offering unparalleled resistance to corrosion, high temperatures, and mechanical stress. Understanding their unique properties, applications, and manufacturing intricacies is crucial for B2B decision-makers and technical personnel aiming to optimize their systems and processes.

The global market for specialty metals and woven filtration media is experiencing sustained growth, driven by innovation in sustainable technologies and stricter regulatory standards. For instance, the demand for materials capable of filtering micro-particles or resisting aggressive chemical attacks has surged. This has placed a significant focus on advanced forms of Stainless Steel Woven Wire Mesh, particularly those crafted from alloys like 904L, which offer superior performance over conventional grades. Our aim is to provide an in-depth analysis of these critical components, ensuring clarity on their technical merits and strategic implementation.

Stainless steel woven wire mesh is fundamentally created from high-quality stainless steel wire, meticulously woven together to form either a square or an oblong opening. This fabrication process imparts exceptional characteristics such as resistance to rust, corrosion, acid, alkali, heat, and chemical degradation, alongside high strength and outstanding durability. These attributes make Stainless Steel Woven Wire Mesh an indispensable component across a vast array of sectors, including industrial processing, architectural design, residential applications, and many other specialized environments.

A key variant, dutch woven wire mesh, stands out due to its unique weaving pattern where the warp wires are generally heavier and spaced further apart than the shute (weft) wires. This creates a dense, robust mesh with extremely fine openings and high filtration capabilities, particularly effective for pressure filtration where precise separation is critical. Unlike standard plain or twilled weaves, the dutch weave offers a higher particle retention efficiency and superior mechanical stability under stress, making it ideal for critical fluid and gas filtration systems in highly demanding industries.

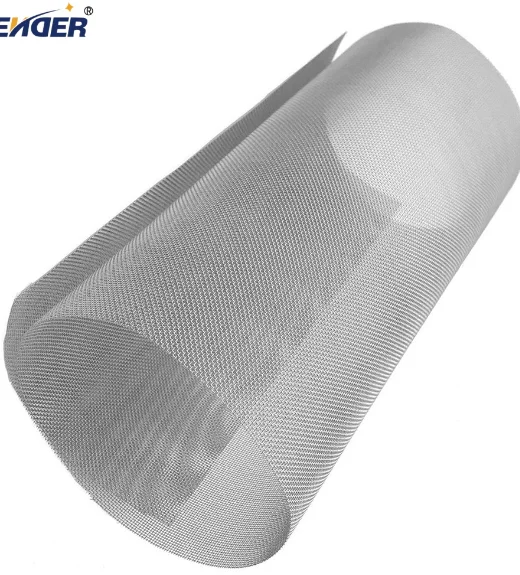

Illustrative example of advanced filtration capabilities using stainless steel woven wire mesh.

While grades like 304 and 316 stainless steel are common for general-purpose steel woven mesh, applications requiring superior corrosion resistance, especially in sulfuric acid environments or against chloride stress corrosion cracking, necessitate specialized alloys. This is where stainless steel 904l sheets come into play. With a higher content of chromium, nickel, molybdenum, and copper, 904L offers exceptional resistance to a broader spectrum of corrosive media, making it a preferred choice for critical infrastructure components where downtime due to material failure is unacceptable.

The production of high-performance materials like dutch woven wire mesh, stainless steel 904l sheets, and general steel woven mesh involves sophisticated processes that ensure superior quality and performance. For woven mesh products, the journey begins with selecting specific stainless steel alloys, which are then drawn into precise wire diameters. This wire drawing process is critical, as it enhances the wire's tensile strength and surface finish, directly influencing the final mesh's durability and filtration efficacy.

For dutch woven wire mesh, the drawn wires undergo a specialized weaving technique on advanced looms. This involves densely packing the weft wires to create a tight, uniform pore structure, ensuring precise filtration. Post-weaving, the mesh may undergo annealing to relieve internal stresses and enhance flexibility, followed by calendering to flatten the mesh and improve its pore distribution. Each step is carefully monitored to adhere to international standards such as ISO 9001 for quality management and ASTM standards for material specifications.

The manufacturing of stainless steel 904l sheets follows a distinct pathway. This typically involves melting high-purity raw materials in an electric arc furnace, followed by secondary refining processes like Argon Oxygen Decarburization (AOD) to achieve the precise chemical composition. The molten steel is then cast into slabs or billets, which are subsequently hot-rolled into sheets. Further cold-rolling and annealing steps refine the thickness, mechanical properties, and surface finish. Stringent non-destructive testing (NDT) methods, including ultrasonic testing and eddy current testing, are applied to detect any internal defects, ensuring the integrity and longevity of the sheets in critical applications.

Key Manufacturing & Quality Control Parameters | ||||

Product Type | Key Process | Primary Material | Inspection Standard | Typical Service Life |

Dutch Woven Wire Mesh | Wire Drawing, Precision Weaving, Annealing, Calendering | SS 304, 316, 316L, 904L | ISO 9001, ASTM E2814 | 3-10+ Years (application dependent) |

Stainless Steel 904L Sheets | Melting, Casting, Hot Rolling, Cold Rolling, Annealing | UNS N08904 (904L) | ASTM A240, ISO 15156 | 10-25+ Years (application dependent) |

General Steel Woven Mesh | Wire Drawing, Standard Weaving | SS 304, 316 | ASTM E2016 | 2-8+ Years (application dependent) |

These meticulous processes, combined with rigorous adherence to international standards like ISO and ASTM, ensure that products such as stainless steel 904l sheets and `dutch woven wire mesh` deliver exceptional performance and extended service life in critical operational environments, minimizing maintenance and replacement costs.

The performance of dutch woven wire mesh and stainless steel 904l sheets is defined by a precise set of technical parameters. For dutch woven wire mesh, critical specifications include mesh count (wires per inch), wire diameter, nominal micron rating (absolute or nominal), and overall thickness. These parameters directly influence filtration efficiency, flow rate, and mechanical strength. For instance, a common specification might be 200 x 1400 mesh, where 200 represents the warp wires and 1400 the shute wires, indicating an extremely fine filtration capability, often down to 5-micron absolute.

In contrast, stainless steel 904l sheets are characterized by their chemical composition (e.g., typically 23-28% Ni, 19-23% Cr, 4-5% Mo, 1-2% Cu), mechanical properties (tensile strength, yield strength, elongation), thickness (from 0.5mm to 50mm+), width, and surface finish. The presence of higher molybdenum and copper content significantly enhances its resistance to sulfuric acid and other non-oxidizing acids, a critical advantage over standard grades like 316L. This specific alloying profile also provides superior pitting and crevice corrosion resistance, essential in harsh chloride environments.

Comparative Technical Specifications | ||||

Feature/Material | Dutch Woven Wire Mesh (Example) | Standard Square Woven Mesh (Example) | SS 904L Sheet (Example) | SS 316L Sheet (Example) |

Typical Mesh Count/Gauge | 200 x 1400 mesh | 100 x 100 mesh | 2.0mm thickness | 2.0mm thickness |

Nominal Micron Rating | 5-10 micron | 150 micron | N/A (solid material) | N/A (solid material) |

Corrosion Resistance | High (depends on alloy) | Good (depends on alloy) | Excellent (high Mo & Cu) | Very Good (low carbon) |

Chemical Resistance (Sulfuric Acid) | Good to Excellent | Moderate | Superior | Moderate |

Pitting Resistance Equivalent Number (PREN) | Varies with grade | Varies with grade | ~34-36 | ~23-25 |

The data clearly illustrates the superior attributes of 904L, making it a robust choice for environments where 316L might falter. Similarly, the unique weave structure of `dutch woven wire mesh` provides significantly finer filtration and mechanical strength compared to standard square woven mesh, justifying its use in precision applications where `steel woven mesh` with wider apertures would be insufficient.

Analyzing filtration efficiency across different mesh types reveals clear performance advantages. For instance, in a typical industrial fluid filtration scenario targeting particles below 20 microns:

· Standard Steel Woven Mesh (e.g., 80 mesh): Achieves approximately 60-70% particle capture for particles >20 microns.

· Fine Square Stainless Steel Woven Wire Mesh (e.g., 200 mesh): Captures 85-90% of particles >10 microns.

· Dutch Woven Wire Mesh (e.g., 200 x 1400 mesh): Demonstrates superior performance, capturing 98-99% of particles >5 microns due to its tight pore structure and enhanced dirt holding capacity.

This trend highlights the specialized capabilities of `dutch woven wire mesh` for precision separation, making it an invaluable asset in pharmaceutical, chemical, and fine particulate processing industries.

The distinct properties of dutch woven wire mesh, stainless steel 904l sheets, and robust steel woven mesh position them across a myriad of demanding industrial applications. In the petrochemical industry, stainless steel 904l sheets are frequently utilized in heat exchangers, pressure vessels, and piping systems handling sulfuric acid or other highly corrosive media. Their exceptional anti-corrosion properties ensure plant integrity and significantly extend the service life of critical infrastructure, directly contributing to enhanced operational safety and reduced maintenance costs.

For precision filtration, particularly in chemical processing, pharmaceuticals, and food & beverage industries, dutch woven wire mesh excels. It is commonly found in filter cartridges, strainers, and filter leaves for separating fine solids from liquids or gases. Its ability to maintain structural integrity under high differential pressures, combined with its precise pore size, ensures consistent product quality and minimizes batch contamination. This specialized mesh also plays a role in energy efficiency by optimizing flow rates in filtration systems, thus reducing pump power consumption.

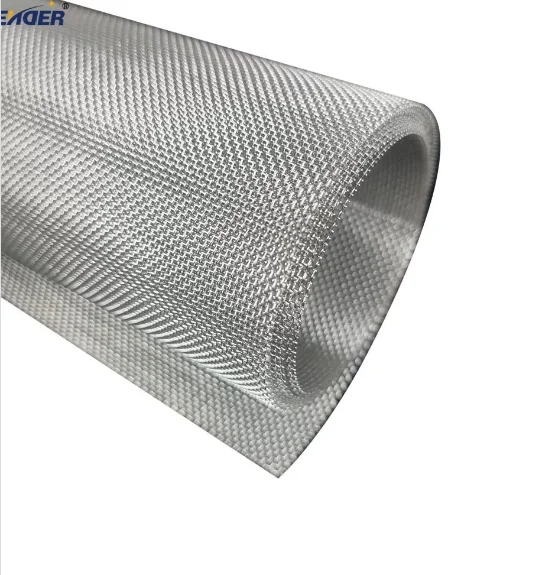

Visual representation of stainless steel components in a complex industrial setting.

General steel woven mesh, often in standard square or plain weave, finds extensive use in broader applications such as water treatment (for pre-filtration and debris removal), mining (as sizing screens and sieves), and general industrial sifting. While not possessing the ultra-fine filtration of dutch weave or the extreme corrosion resistance of 904L, its robustness and cost-effectiveness make it a go-to solution for less aggressive environments where mechanical strength and basic separation are primary concerns. These materials collectively ensure process reliability and contribute to overall system efficiency across various sectors.

Choosing the right supplier for critical materials like dutch woven wire mesh, stainless steel 904l sheets, and steel woven mesh requires a thorough evaluation of several key criteria. Beyond competitive pricing, B2B buyers must prioritize manufacturers demonstrating exceptional quality control, robust certifications, and a proven track record of reliability. A reputable manufacturer will possess certifications like ISO 9001:2015, ensuring consistent product quality and adherence to internationally recognized management standards.

Experience plays a vital role; look for suppliers with extensive service years in the industry and a deep understanding of metallurgical science and weaving technologies. Their expertise ensures that the chemical composition of stainless steel 904l sheets meets precise UNS N08904 standards and that `dutch woven wire mesh` exhibits consistent micron ratings. Furthermore, the capacity for customization is crucial. Leading manufacturers should offer tailored solutions, whether it's specific mesh configurations, non-standard sheet dimensions, or specialized finishes, to perfectly match unique application requirements.

Other critical factors include lead times, which directly impact project schedules, and comprehensive after-sales support. A manufacturer's ability to provide technical assistance, perform material testing, and offer prompt customer service enhances trustworthiness and builds long-term partnerships. Engaging with manufacturers who can provide detailed material certifications, test reports, and traceability documentation validates the authenticity and quality of the materials supplied, fostering confidence in their products and services.

Recognizing that no two industrial applications are identical, leading suppliers offer extensive customization capabilities for Stainless Steel Woven Wire Mesh products. For `dutch woven wire mesh`, this can involve specifying unique warp and weft wire diameters, creating custom mesh counts to achieve precise micron ratings, or fabricating the mesh into various forms such as filter discs, cylinders, or cones. Customization ensures optimal performance, enhancing filtration efficiency and extending the service life of filtration units in specialized processes where off-the-shelf solutions may fall short.

For stainless steel 904l sheets, customization extends to non-standard dimensions, specific thickness tolerances, and tailored surface finishes (e.g., 2B, BA, No.1, polished) to meet aesthetic or functional requirements. Clients may also require specialized cutting, profiling, or even welding of 904L sheets into complex fabricated components for corrosive environments. Collaborating closely with engineering teams, manufacturers can develop bespoke solutions that fully integrate into existing systems or facilitate new designs, addressing challenges related to corrosion, temperature, and pressure unique to each project.

Even for general steel woven mesh, customization options are available, including varying mesh sizes, wire gauges, and roll widths to suit diverse screening, sifting, or reinforcement applications. The ability to provide tailored solutions, backed by technical expertise and advanced manufacturing facilities, is a hallmark of an authoritative supplier. This ensures that customers receive products perfectly aligned with their operational demands, preventing costly modifications or performance compromises down the line. We pride ourselves on offering comprehensive engineering support to bring complex visions to fruition.

The practical application of `dutch woven wire mesh`, `stainless steel 904l sheets`, and `steel woven mesh` demonstrates their tangible benefits across various industries. Consider a leading pharmaceutical company that sought to upgrade its process fluid filtration system to meet stringent purity standards. By implementing custom-fabricated dutch woven wire mesh filter elements with an absolute micron rating of 5, they achieved a significant reduction in product contamination by 15% and extended the lifespan of their downstream equipment, resulting in a 20% decrease in operational downtime. This specific application highlighted the mesh's robust structure and precise filtration capabilities under continuous operation.

In another instance, a major chemical plant faced recurring failures in their sulfuric acid storage tanks and piping due to severe corrosion, impacting their production schedule. The traditional 316L stainless steel components were unable to withstand the aggressive environment. After consulting with our material experts, they switched to components manufactured from stainless steel 904l sheets. The enhanced resistance to both general and localized corrosion provided by 904L resulted in a remarkable 95% reduction in corrosion-related incidents over a five-year period, effectively eliminating costly unscheduled maintenance and ensuring uninterrupted production. This case exemplifies the long-term cost-saving potential and reliability of choosing the appropriate high-performance alloy.

Furthermore, an international mining operation utilized heavy-duty steel woven mesh for their ore classification screens. The previous screens suffered from rapid wear and tear due to abrasive materials and high impact forces. By employing specially manufactured `Stainless Steel Woven Wire Mesh` with larger wire diameters and precise aperture sizes, the mine was able to increase throughput by 10% due to reduced screen clogging and achieved a 30% extension in screen life, significantly improving operational efficiency and lowering replacement costs. These examples underscore our commitment to delivering material solutions that address complex industrial challenges, providing measurable improvements in performance and profitability for our clients.

Trustworthiness is built on a foundation of unwavering quality assurance and comprehensive customer support. Our commitment to excellence is underscored by rigorous adherence to international standards, including ISO 9001:2015 certification for quality management systems. Every batch of stainless steel 904l sheets undergoes extensive material testing, including chemical analysis, mechanical property verification, and non-destructive evaluations, with full traceability reports provided. Similarly, each roll of dutch woven wire mesh and steel woven mesh is subjected to dimensional checks, pore size analysis, and flow rate tests to ensure it meets stringent performance specifications.

We stand behind the durability and performance of our Stainless Steel Woven Wire Mesh products with a robust warranty program, offering peace of mind to our B2B partners. Our standard delivery cycles are transparent and communicated upfront, with agile logistics capabilities to accommodate urgent requirements. Furthermore, our dedicated customer support team and technical experts are available to provide assistance, from initial product selection and design consultation to post-installation troubleshooting. This holistic approach ensures that our clients not only receive high-quality materials but also benefit from expert guidance and reliable service throughout the product lifecycle.

We understand that the success of your operations often depends on the reliability of your supply chain. Therefore, we emphasize transparent communication regarding production progress, quality control results, and shipping logistics. Our long-standing relationships with global industries are a testament to our commitment to delivering not just products, but complete material solutions backed by integrity and expertise.

A1: Dutch woven wire mesh features a denser weave with smaller, more uniform pore openings compared to standard square mesh. This unique structure provides superior filtration efficiency, higher mechanical strength, and excellent dirt-holding capacity, making it ideal for precision pressure filtration applications where fine particle separation is critical.

A2: Stainless steel 904l sheets are an austenitic stainless steel alloy with high contents of chromium, nickel, molybdenum, and copper. This composition grants it exceptional resistance to sulfuric acid, phosphoric acid, and other non-oxidizing acids, as well as superior resistance to pitting and crevice corrosion in chloride-rich environments, outperforming standard 316L.

A3: General steel woven mesh, including standard Stainless Steel Woven Wire Mesh (e.g., 304 or 316 grades), is widely used for broad-spectrum screening, sifting, and separation tasks. Common applications include pre-filtration in water treatment, aggregate sizing in mining, insect screens, security fences, and general industrial sieving where high precision is not the primary requirement.

A4: Yes, all our Stainless Steel Woven Wire Mesh products, including dutch woven wire mesh and stainless steel 904l sheets, are manufactured under strict quality control protocols and comply with relevant international standards such as ISO 9001:2015, ASTM, and ANSI. We provide material certifications and test reports upon request.

A5: Absolutely. We specialize in providing customized solutions. For steel woven mesh and dutch woven wire mesh, we can tailor mesh counts, wire diameters, roll widths, and shapes (e.g., discs, cylinders). For stainless steel 904l sheets, we offer custom dimensions, thicknesses, and surface finishes to meet specific project requirements.

A6: Lead times vary depending on the specific product, quantity, and customization requirements. For large orders of stainless steel 904l sheets, typical lead times can range from 4 to 8 weeks. We strive to provide accurate estimates at the time of quotation and communicate progress transparently throughout the manufacturing process.

A7: Yes, our team of experienced engineers and material specialists is available to provide comprehensive technical support. We assist clients in evaluating their specific application conditions, fluid types, temperature ranges, and pressure requirements to recommend the most suitable Stainless Steel Woven Wire Mesh, including appropriate material grades and weave types like dutch woven wire mesh, ensuring optimal performance and longevity.

The strategic deployment of high-performance materials such as dutch woven wire mesh, stainless steel 904l sheets, and precision steel woven mesh is indispensable for modern industrial excellence. These specialized products offer robust solutions to complex challenges, ranging from ultra-fine filtration to extreme corrosion resistance. By understanding the intricate manufacturing processes, specific technical parameters, and diverse application benefits, B2B decision-makers can make informed choices that enhance operational efficiency, ensure product quality, and significantly extend equipment lifespan.

Our commitment to providing superior Stainless Steel Woven Wire Mesh solutions is backed by extensive expertise, rigorous quality control, and a customer-centric approach. We empower industries to achieve greater reliability and sustainability through materials engineered for the future. Partner with us to leverage cutting-edge material science and tailored solutions that meet the exacting demands of your most critical applications.

1. ASM Handbook, Volume 1: Properties and Selection: Irons, Steels, and High-Performance Alloys. ASM International.

2. Standards of the Welded Steel Tube Institute. ASTM International.

3. Corrosion Engineering: Principles and Practice. Marcel Dekker, Inc.

4. Filtration and Separation Handbook. Elsevier Science.

5. ISO 9001:2015 Quality Management Systems – Requirements. International Organization for Standardization.

Contact Information

Quick Link

Product

copyright

Please leave us a message and we will get back to you shortly.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.