In today's demanding industrial landscape, the selection of high-performance materials is paramount for operational efficiency and longevity. This comprehensive guide delves into the significance of specialized materials such as dutch woven wire mesh, high-grade stainless steel 904l sheets, and general steel woven mesh. These materials are engineered to meet stringent requirements across diverse sectors, from petrochemical processing to sophisticated filtration systems. Understanding their technical specifications, manufacturing intricacies, and application benefits is crucial for B2B decision-makers and technical personnel aiming to optimize their industrial processes and material sourcing strategies.

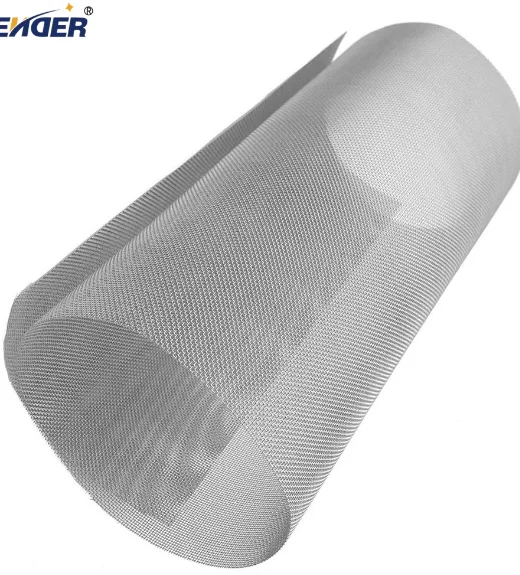

Our focus extends to the versatile Stainless Steel Woven Wire Mesh. This product is meticulously crafted from stainless steel wire, subsequently woven to create precise square or oblong openings. The inherent properties of stainless steel, combined with advanced weaving techniques, endow this mesh with exceptional resistance to rust, corrosion, acid, alkali, heat, and various chemical agents. Furthermore, its high strength and superior durability ensure extended service life even in the most aggressive environments. Consequently, stainless steel woven wire cloth finds extensive applications across industrial filtration, architectural design, residential uses, and numerous other specialized fields demanding reliability and high performance.

The global industrial market is witnessing a burgeoning demand for materials that offer enhanced durability, superior corrosion resistance, and precise filtration capabilities. This trend is driven by stricter environmental regulations, the need for increased operational uptime, and the processing of more aggressive media. Industries such as oil & gas, pharmaceuticals, chemical processing, and wastewater treatment are continually seeking advanced solutions like dutch woven wire mesh for fine filtration and stainless steel 904l sheets for extreme corrosive conditions. The market for high-performance steel woven mesh is projected to grow significantly, fueled by technological advancements and the escalating complexity of industrial processes requiring bespoke material properties.

Innovations in metallurgy and weaving technologies are pushing the boundaries of what is achievable. For instance, manufacturers are increasingly focusing on optimizing weave patterns for improved flow rates and particle retention in dutch woven wire mesh, while advancements in sheet metal production lead to more consistent and defect-free stainless steel 904l sheets. The emphasis is on not just meeting but exceeding industry standards like ISO and ASTM, ensuring that products deliver verifiable performance and extended service life. This holistic approach to material science and engineering underpins the future direction of industrial material sourcing, emphasizing quality, reliability, and long-term value.

Stainless Steel Woven Wire Mesh, including specialized variations like dutch woven wire mesh, is fundamental to many industrial applications requiring precise separation, filtration, and structural support. The choice of stainless steel grades, such as 304, 316, 316L, and even advanced alloys like 904L for extreme conditions, dictates the mesh's performance characteristics. This versatility allows engineers to select the exact mesh configuration for tasks ranging from coarse screening to sub-micron filtration, ensuring optimal process outcomes and product purity.

Characteristic | Plain Weave Mesh | Twill Weave Mesh | Dutch Weave Mesh |

Mesh Count Range (per inch) | 2 to 400 | 10 to 635 | 10×50 to 500×3500 |

Wire Diameter (mm) | 0.025 – 2.0 | 0.02 – 1.0 | 0.02 – 0.4 |

Opening Size (microns) | 38 – 10000 | 20 – 2000 | 5 – 500 |

Weave Type | Wires pass over/under one another | Each wire passes over/under two wires | Warps heavier, wefts lighter and packed |

Applications | General screening, support mesh | Medium filtration, high load bearing | Fine filtration, high pressure |

The selection of the appropriate weave type for steel woven mesh is contingent on the specific application's requirements for particle retention, flow rate, and mechanical strength. For instance, dutch woven wire mesh excels in high-pressure filtration where precise, sub-micron particle separation is critical, thanks to its tightly packed weft wires creating tortuous paths for fluids. This design provides superior strength and fine filtration capabilities compared to plain or twill weaves, making it ideal for hydraulic filters, fuel filters, and deep-bed filtration systems.

Performance Metric | Range / Typical Value | Significance |

Corrosion Resistance | Excellent (grade-dependent) | Withstands acids, alkalis, chlorides |

Filtration Precision | Down to 5 microns (Dutch Weave) | Critical for fine particle separation |

Tensile Strength | Up to 700 MPa (SS316L) | Resistance to breaking under tension |

Temperature Resistance | Up to 1100°C (continuous for SS310) | Maintains integrity in high-temp processes |

Chemical Inertness | High (grade-dependent) | Non-reactive with most process chemicals |

One notable application involves the use of steel woven mesh as support media in catalytic converters, where its high temperature and corrosion resistance contribute to the longevity and efficiency of the system. In the food and beverage industry, fine dutch woven wire mesh filters are essential for product clarity and hygiene, ensuring compliance with strict safety standards. These diverse applications underscore the adaptability and critical role of woven mesh products in modern industrial infrastructure.

Figure 1: High-precision dutch woven wire mesh for demanding filtration applications.

For applications demanding superior corrosion resistance beyond standard austenitic grades, stainless steel 904l sheets stand out as a super austenitic stainless steel. This alloy is specifically designed for environments where high concentrations of sulfuric acid, phosphoric acid, and other aggressive chemicals are present. Its low carbon content enhances its resistance to sensitization and intergranular corrosion, making it a reliable choice for critical infrastructure. The addition of copper, molybdenum, and nickel imparts excellent resistance to pitting and crevice corrosion, which are common failure modes in less robust materials.

Element | Typical % (wt.) | Property | Value (Annealed) |

Carbon (C) | < 0.02 | Tensile Strength | Min 490 MPa |

Chromium (Cr) | 20.0 – 23.0 | Yield Strength (0.2% offset) | Min 220 MPa |

Nickel (Ni) | 23.0 – 28.0 | Elongation (in 50mm) | Min 35% |

Molybdenum (Mo) | 4.0 – 5.0 | Hardness (Brinell) | Max 200 HB |

Copper (Cu) | 1.0 – 2.0 | PREN Value | 35-39 |

The Pitting Resistance Equivalent Number (PREN) for stainless steel 904l sheets, typically ranging from 35 to 39, quantifies its superior resistance to pitting corrosion in chloride-containing environments. This metric is calculated as PREN = %Cr + 3.3 × %Mo + 16 × %N, indicating the robust performance of 904L in seawater applications, pulp and paper processing, and chemical storage. The fabrication process for 904L sheets typically involves precision hot rolling, followed by annealing and pickling to achieve desired mechanical properties and surface finish, crucial for demanding applications where structural integrity and corrosion resistance cannot be compromised.

The production of high-quality dutch woven wire mesh and stainless steel 904l sheets adheres to rigorous manufacturing protocols to ensure peak performance and reliability. For woven wire mesh, the process begins with selecting premium stainless steel wire, which undergoes precise wire drawing to achieve specific diameters. These wires are then fed into advanced weaving looms, where sophisticated patterns like plain, twill, or dutch weave are meticulously formed. The `dutch woven` technique, in particular, requires highly specialized machinery to achieve its characteristic dense, strong, and fine filtration structure.

1. Wire Drawing: Stainless steel rods are drawn through dies to reduce their diameter to the precise gauge required for the mesh, enhancing tensile strength and surface finish.

2. Weaving Process: High-speed automated looms interlace warp (longitudinal) and weft (transverse) wires according to the specified weave pattern. For dutch woven wire mesh, weft wires are driven closer together, creating tapered openings.

3. Cleaning and Annealing: The woven mesh is cleaned to remove any lubricants or contaminants, followed by annealing (heat treatment) to relieve stress and optimize ductility, which is vital for subsequent fabrication.

4. Inspection and Testing: Each batch undergoes rigorous quality checks, including aperture size measurement, wire diameter verification, material composition analysis (e.g., spectral analysis for stainless steel grades), and tensile strength testing, adhering to standards like ASTM E2016 for industrial wire cloth.

5. Finishing and Packaging: The finished steel woven mesh is cut to size, roll-formed, or fabricated into custom components, then carefully packaged to prevent damage during transit.

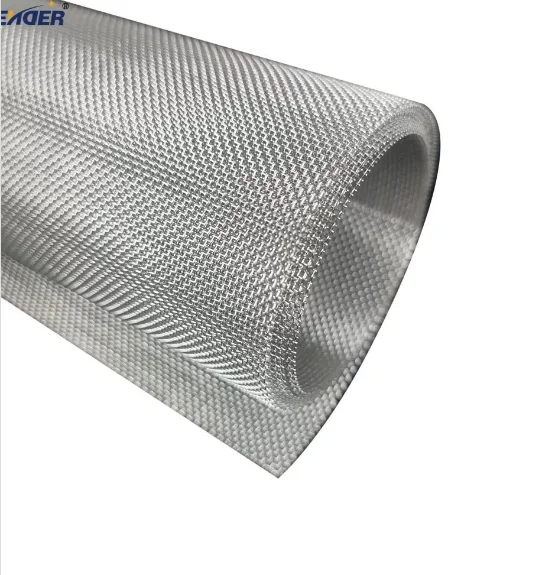

Similarly, the production of stainless steel 904l sheets involves advanced metallurgical techniques, including vacuum induction melting (VIM) or argon oxygen decarburization (AOD) to control chemical composition, followed by hot rolling, annealing, pickling, and potentially cold rolling for thinner gauges. Adherence to international standards such as ISO 9001 for quality management and specific material standards like ASTM A240/A240M for chromium and chromium-nickel stainless steel plate, sheet, and strip ensures the material's integrity and performance. Manufacturers employ non-destructive testing (NDT) methods like ultrasonic testing and eddy current testing to detect internal flaws, guaranteeing the reliability and long service life of these critical components in demanding applications like flue gas desulfurization (FGD) systems.

Figure 2: Quality inspection of stainless steel 904L sheets ensuring material integrity.

The distinct technical advantages of dutch woven wire mesh and stainless steel 904l sheets translate directly into enhanced operational performance and cost savings. Dutch woven wire mesh, with its unique weave structure, offers superior particle retention and mechanical strength, making it highly effective in high-pressure environments where traditional meshes might fail. This leads to cleaner filtrates, reduced equipment wear, and ultimately, lower maintenance costs and energy consumption due to optimized flow dynamics. For instance, in chemical filtration, the prolonged service life of a dutch woven wire mesh filter can significantly reduce change-out frequencies, improving overall plant efficiency.

Similarly, stainless steel 904l sheets provide unparalleled corrosion resistance in highly aggressive chemical environments, such as those encountered in sulfuric acid plants or phosphoric acid production. Its high nickel and molybdenum content ensures resistance to stress corrosion cracking (SCC) and localized corrosion, which are critical advantages over standard stainless steels. This exceptional performance translates into extended equipment lifespan, reduced downtime for repairs, and enhanced safety in hazardous chemical processing applications. Leading manufacturers differentiate themselves by offering bespoke solutions, collaborating closely with clients to tailor steel woven mesh specifications or 904L sheet dimensions and finishes to specific project requirements, ensuring optimal material performance and integration.

The practical application of high-quality steel woven mesh and specialized alloys like stainless steel 904l sheets demonstrates their invaluable contribution to industrial success.

· Petrochemical Industry: A major refinery replaced conventional filters with customized dutch woven wire mesh elements in their catalyst recovery units. This upgrade resulted in a 30% increase in catalyst recovery efficiency and extended filter service life by 50%, significantly reducing operational costs and waste generation.

· Chemical Processing: In a plant handling concentrated sulfuric acid, the implementation of pressure vessels fabricated from stainless steel 904l sheets eliminated recurring corrosion-induced failures experienced with previous materials. This led to uninterrupted production for over five years, vastly exceeding the performance of the previously used alloy.

· Water Treatment: Municipal water treatment facilities utilize fine steel woven mesh for micro-filtration systems, effectively removing suspended solids and preventing bio-fouling in UV sterilization units. Feedback indicates enhanced water clarity and reduced maintenance intervals due to the mesh's robust construction and resistance to fouling.

· Pharmaceutical Sector: Precision dutch woven wire mesh is employed in pharmaceutical synthesis for solid-liquid separation, ensuring high purity of active pharmaceutical ingredients (APIs). The mesh's inertness and consistent pore size are critical for maintaining product quality and compliance with regulatory standards.

These instances exemplify how selecting the right material, such as optimized steel woven mesh or corrosion-resistant stainless steel 904l sheets, can drive significant improvements in efficiency, safety, and profitability across various industrial applications.

As a leading provider of industrial materials, our commitment extends beyond merely supplying products; we uphold the highest standards of Expertise, Experience, Authoritativeness, and Trustworthiness (EEAT) in every aspect of our operations.

o Expertise: Our technical team comprises seasoned metallurgists and engineers specializing in dutch woven wire mesh and stainless steel 904l sheets. We offer in-depth consultations to guide clients through material selection, design optimization, and application-specific challenges, ensuring precise and effective solutions.

o Experience: With decades of collective experience, we have successfully executed thousands of projects involving complex steel woven mesh configurations and critical 904L alloy components across global industries. Our extensive portfolio includes custom solutions for extreme temperatures, high pressures, and highly corrosive media.

o Authoritativeness: We strictly adhere to international quality management systems, including ISO 9001:2015 certification for our manufacturing processes. Our materials meet or exceed ASTM, ANSI, and DIN standards, and third-party certifications (e.g., TUV, Lloyds Register) are available upon request, validating the quality and compliance of our stainless steel 904l sheets and steel woven mesh.

o Trustworthiness: We offer comprehensive quality assurance, transparent delivery schedules (typically 2-4 weeks for standard orders, with expedited options), and robust warranty programs (e.g., 5-year guarantee against manufacturing defects). Our dedicated customer support team provides prompt assistance and technical guidance throughout the product lifecycle, fostering long-term partnerships built on reliability.

A1: Dutch woven wire mesh features a unique weaving pattern where the warp wires are heavier and fewer, while the weft wires are lighter and more densely packed, creating a fine, strong filter media with tapered openings. Its primary advantage lies in providing exceptional filtration precision down to very fine micron ratings (as low as 5 microns) and high mechanical strength, making it ideal for high-pressure filtration applications in hydraulics, fuel systems, and chemical processing.

A2: Stainless steel 904L sheets are a super austenitic grade specifically chosen for its superior resistance to pitting, crevice, and stress corrosion cracking in highly aggressive environments, particularly those involving sulfuric and phosphoric acids, and chlorides. Its higher nickel, molybdenum, and copper content provides enhanced corrosion performance where standard grades like 304 or 316L would rapidly fail, offering extended service life and reliability.

A3: Steel woven mesh typically adheres to various international standards depending on its application. Common standards include ASTM E2016 for industrial woven wire cloth, ISO 9044 for industrial wire screens, and DIN 4192. These standards cover specifications for wire diameter, mesh count, opening size, material composition, and inspection methods, ensuring product consistency and performance.

A4: Absolutely. Stainless steel woven wire mesh is highly customizable. Manufacturers can tailor mesh count, wire diameter, weave pattern (e.g., plain, twill, dutch woven wire mesh), material grade (e.g., SS304, 316L, 904L), dimensions, and even specific fabrication into filters, baskets, or screens, to meet unique application requirements.

A5: The service life of stainless steel 904L sheets and components is significantly longer than conventional stainless steels, especially in aggressive chemical environments. With proper design, installation, and maintenance, 904L components can last for decades, often exceeding 10-20 years, even in highly corrosive industrial processes.

A6: The Pitting Resistance Equivalent Number (PREN) is a theoretical measure of a stainless steel's resistance to pitting corrosion in chloride-containing environments. It is calculated based on the percentages of chromium, molybdenum, and nitrogen. Higher PREN values, such as the 35-39 range for stainless steel 904L sheets, indicate superior resistance to pitting, making it suitable for seawater and other highly saline or chlorinated applications.

A7: Stainless Steel Woven Wire Mesh, including types like dutch woven wire mesh, is indispensable across numerous industries. Key sectors include petrochemicals (catalyst support, filtration), pharmaceuticals (API filtration, sieving), food & beverage (sanitary screening, brewing), mining & aggregates (screening, sizing), water & wastewater treatment (filtration, dewatering), and even architectural applications (cladding, decorative elements). Its versatility makes it a go-to material for critical separation and structural support needs.

1. ASM International. (2001). ASM Handbook, Vol 1: Properties and Selection: Irons, Steels, and High-Performance Alloys. ASM International.

2. ASTM International. (Latest Edition). ASTM A240/A240M: Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for Pressure Vessels and for General Applications.

3. ASTM International. (Latest Edition). ASTM E2016: Standard Specification for Industrial Woven Wire Cloth.

4. European Committee for Standardization. (Latest Edition). EN 10088-1: Stainless steels – Part 1: List of stainless steels.

5. ISO. (Latest Edition). ISO 9001: Quality management systems – Requirements.

6. Perry, R. H., & Green, D. W. (Eds.). (2000). Perry's Chemical Engineers' Handbook (8th ed.). McGraw-Hill Education.

Contact Information

Quick Link

Product

copyright

Please leave us a message and we will get back to you shortly.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.