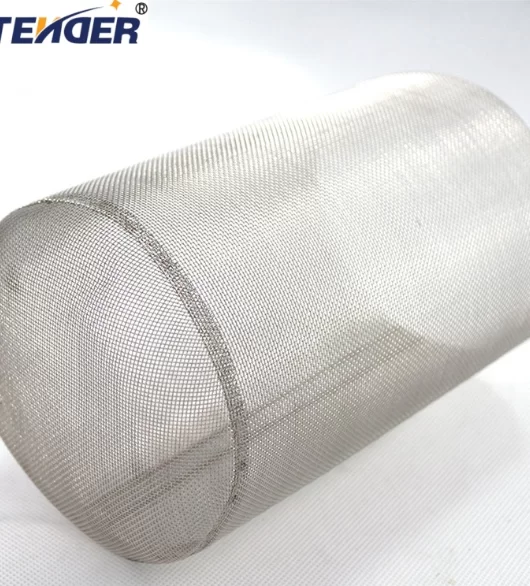

In the intricate landscape of modern industrial operations, efficient and reliable filtration is paramount for process integrity, equipment protection, and product quality. Woven Wire Mesh Filter Tubes and Filter Cartridges stand as critical components, offering robust solutions for separating particulate impurities from liquids and gases. These cylindrical filter elements are meticulously formed by rolling, welding, or edging high-grade stainless steel woven metal wire mesh, providing a simple yet exceptionally effective structure with strong permeability. Widely deployed across diverse sectors such as petroleum, chemical, pharmaceutical, water treatment, food, and machinery, their versatility makes them indispensable for primary filtration and safeguarding delicate equipment or pipeline systems. Our expertise extends to a comprehensive range of custom metal mesh filters, including precision brass mesh filter, resilient filter steel mesh, and robust galvanised mesh filters, each engineered to meet specific industrial demands.

The demand for sophisticated filtering mesh solutions is continuously driven by evolving industry standards, stringent environmental regulations, and the pursuit of operational efficiency. From fine mesh filter applications requiring sub-micron accuracy to heavy-duty filter metal mesh for aggressive environments, the core principle remains consistent: reliable particle retention. This article delves into the technical aspects, manufacturing prowess, and diverse applications of these vital filtration technologies, highlighting how custom solutions provide optimal performance and longevity for critical industrial processes. Understanding the nuances of material selection, manufacturing precision, and application-specific advantages is key to unlocking the full potential of these essential components.

The selection of an appropriate filter mesh hinges on a multitude of technical parameters, including material composition, micron rating, temperature resistance, and corrosive environment compatibility. Each specific application

dictates the optimal choice, whether it's an inline stainless steel mesh filter for high-purity processes or a brass mesh filter for specific chemical interactions. Understanding these variations is crucial for engineers and procurement specialists to ensure peak performance and system longevity. Below is a comparative overview of common metal mesh filter types.

Parameter | Stainless Steel Mesh Filter (e.g., 304L/316L) | Brass Mesh Filter | Galvanised Mesh Filters | Specialty Alloys (e.g., Monel, Hastelloy) |

Material Composition | Iron-chromium-nickel alloy, 304L (low carbon), 316L (molybdenum for enhanced corrosion). | Copper-zinc alloy (typically 65% Copper, 35% Zinc). | Low carbon steel coated with a layer of zinc. | Nickel-based alloys, offering superior resistance to extreme temperatures and corrosive media. |

Micron Rating Range | Typically 2 µm to 2000 µm, enabling fine mesh filter applications. | Generally 20 µm to 1000 µm, good for general purpose filtering mesh. | Typically 50 µm to 5000 µm, for coarse filtration. | Sub-micron to 100 µm for highly specialized processes. |

Operating Temperature | Up to 800°C (1472°F) for 316L, excellent for high-temp environments. | Up to 200°C (392°F), limited by zinc content. | Up to 200°C (392°F), limited by zinc melting point. | Over 1000°C (1832°F), depending on alloy, for extreme conditions. |

Corrosion Resistance | Excellent against rust, weak acids, and some bases. 316L offers superior resistance to chlorides. Critical for filter steel mesh in harsh conditions. | Good against fresh water, fuels, and organic chemicals. Poor against strong acids/bases. | Good against atmospheric corrosion due to zinc coating. Susceptible to strong acids/bases once zinc is compromised. | Outstanding in highly aggressive corrosive environments, including hot acids and oxidizing agents. |

Typical Applications | Chemicals, pharmaceuticals, food & beverage, water treatment, oil & gas, general industrial filtration. Ideal for inline stainless steel mesh filter systems. | Fuel filtration, plumbing, general purpose liquid filtration where non-corrosive liquids are present. | Construction, agriculture, security, and less critical industrial processes where cost-effectiveness is key. | Aerospace, nuclear, high-purity chemical processing, extreme temperature applications. |

This table highlights the diverse capabilities across different metal mesh types. For instance, while a simple filtering mesh might suffice for basic applications, complex processes often demand the precise engineering of custom metal mesh filters to achieve optimal operational parameters. Our detailed understanding of these specifications allows us to recommend and fabricate the most suitable filter metal mesh for any given industrial requirement, ensuring both efficacy and cost-efficiency.

The production of high-quality woven wire mesh filter tubes and cartridges is a multi-stage process demanding precision, advanced machinery, and rigorous quality control. Our manufacturing pipeline ensures that whether we are creating a brass mesh filter or a sophisticated inline stainless steel mesh filter, the final product adheres to the highest industry standards. This intricate process transforms raw wire materials into durable, high-performance filtration components suitable for critical industrial applications.

The journey begins with selecting premium-grade raw materials. For filter steel mesh, this typically involves 304L or 316L stainless steel wires, known for their excellent corrosion resistance and mechanical strength. For brass mesh filter applications, high-purity brass alloys are chosen for their specific chemical compatibility. These wires are then precisely woven on advanced looms to create various mesh patterns, including plain weave, twill weave, and Dutch weave, each offering distinct filtration characteristics and pore sizes essential for filtering mesh effectiveness. This stage dictates the ultimate filtration accuracy, from coarse to fine mesh filter capabilities.

Once the woven wire mesh is produced, it is precisely cut to specific dimensions required for the filter tube or cartridge. This step is critical for custom metal mesh filters, where precise measurements ensure a perfect fit within existing systems. The cut mesh sheets are then rolled into a cylindrical shape. This forming process is carefully controlled to maintain the structural integrity of the mesh and ensure uniform diameter, which is vital for efficient inline stainless steel mesh filter operation.

The cylindrical mesh is then seamed using advanced welding techniques, such as spot welding or argon arc welding, ensuring a robust and leak-proof joint. For enhanced structural stability and to prevent unraveling, the ends of the filter element are often edged or fitted with end caps. This could involve crimping, soldering, or attaching metal end-fittings. For galvanised mesh filters, post-fabrication galvanization might be applied, or pre-galvanized wire used, depending on design. These processes are critical for the durability and longevity of the filter, contributing significantly to its overall lifespan.

Every Woven Wire Mesh Filter Tube undergoes stringent quality checks to meet industry standards like ISO 9001 and often specific application standards such as ASTM or ANSI. Inspection includes visual checks for defects, dimensional verification, pore size analysis, and pressure testing to confirm structural integrity and filtration performance. This meticulous quality assurance process guarantees that each filter metal mesh product delivers reliable performance and meets our commitment to excellence. We employ advanced optical inspection systems to ensure even the finest mesh filter elements meet specifications.

This precise manufacturing methodology ensures that our filtering mesh products, from standard designs to highly specialized custom metal mesh filters, consistently meet the demanding requirements of various industrial environments, contributing to energy efficiency and corrosion resistance in applications such as petrochemical, metallurgy, and water treatment.

Woven Wire Mesh Filter Tubes and Cartridges offer a host of technical advantages that make them superior in many industrial filtration contexts. Their robust construction, combined with precise filtration capabilities, makes them ideal for a wide array of application scenarios, from basic particulate removal to highly specialized process separations. The versatility allows for implementation of everything from a robust filter steel mesh to a delicate fine mesh filter.

· Durability and Longevity: Constructed from high-strength metal alloys, these filters are designed for extended operational life, resisting wear, tear, and deformation even under high pressure and temperature conditions. This is particularly evident in filter steel mesh solutions.

· High Permeability and Flow Rate: The precise weaving patterns allow for efficient fluid passage with minimal pressure drop, leading to energy savings and optimized system performance. This efficiency is critical for many inline stainless steel mesh filter applications.

· Corrosion and Chemical Resistance: Depending on the material (e.g., 316L stainless steel, Monel, or brass mesh filter), these filters can withstand aggressive chemicals and corrosive environments, ensuring purity and preventing system contamination.

· Cleanability and Reusability: Many woven mesh filters, especially those made from stainless steel, can be easily backwashed or cleaned, significantly reducing operational costs and environmental impact by extending their service life. This feature makes filter metal mesh a sustainable choice.

· Precision Filtration: From coarse filtration to ultra-fine mesh filter applications, the controlled pore size ensures consistent and reliable particle removal, meeting stringent product quality specifications. Our custom metal mesh filters can achieve specific micron ratings.

Typical Application Scenarios:

§ Petrochemical Industry: Filtration of crude oil, natural gas, and refined products; catalyst recovery; protection of pumps and nozzles.

§ Water Treatment: Pre-filtration for reverse osmosis systems, municipal water purification, industrial wastewater treatment. Galvanised mesh filters are often used for coarser pre-filtration stages.

§ Food and Beverage: Clarification of beverages, removal of suspended solids in food processing, sanitary filtration for product integrity.

§ Pharmaceuticals: Pre-filtration for sterile processes, purification of active pharmaceutical ingredients (APIs), solvent filtration. Requires ultra-fine mesh filter elements.

§ Machinery and Hydraulics: Protection of hydraulic systems from particulate contamination, ensuring smooth operation and reducing wear on components. Filtering mesh prevents costly downtime.

Our filters are engineered to excel in these environments, offering solutions that enhance efficiency, extend equipment life, and reduce maintenance costs. Whether it’s an inline stainless steel mesh filter protecting sensitive sensors or a robust filter metal mesh safeguarding large pumps, our products deliver consistent, reliable performance.

In the highly specialized field of industrial filtration, off-the-shelf solutions often fall short of meeting unique process requirements. This is where the capability for custom metal mesh filters becomes indispensable. Our firm excels in providing bespoke woven wire mesh filter tubes and cartridges, meticulously designed to precise specifications, ensuring optimal integration and performance within your existing or new systems. This commitment to customization distinguishes us in a crowded market.

When evaluating manufacturers for filter metal mesh, several factors must be considered beyond just price. Quality, technical support, customization capabilities, and adherence to international standards are paramount. Below is a conceptual comparison reflecting typical attributes, demonstrating why a partner committed to innovation and quality delivers superior long-term value.

Feature/Attribute | Our Company (Specialized, B2B Focus) | Generic Manufacturer (Mass Market) |

Customization Capability | Extensive engineering support for custom metal mesh filters, including material, dimension, and micron rating (e.g., specific fine mesh filter designs). | Limited to standard sizes and materials; minimal flexibility for unique filtering mesh needs. |

Quality Certifications | ISO 9001:2015 certified, adherence to ASTM, ANSI, and often industry-specific standards (e.g., FDA compliance for food applications). | Basic certifications, less emphasis on stringent testing or process control for filter steel mesh. |

Technical Support & Expertise | Dedicated engineering team, application specialists, deep knowledge of brass mesh filter to inline stainless steel mesh filter. | Standard customer service, limited technical depth for complex issues. |

Material Traceability | Full traceability of raw materials and manufacturing steps, crucial for regulated industries. | Often limited or no material traceability, impacting product integrity and compliance. |

After-Sales Support & Warranty | Comprehensive warranty (e.g., 2-year product warranty), responsive customer support, spare parts availability. | Minimal or no warranty, limited post-purchase support. |

Our commitment to quality, technical excellence, and customer-centric solutions positions us as a trusted partner for critical filtration needs. We understand that a filter metal mesh is not just a component; it's an integral part of your operational efficiency and product quality.

Real-world application demonstrates the tangible benefits of high-quality woven wire mesh filters. Our collaboration with leading industries consistently yields improved operational metrics and significant cost savings. These examples highlight the versatility and effectiveness of our filter steel mesh, brass mesh filter, and inline stainless steel mesh filter solutions.

A major chemical plant experienced frequent clogging and damage to its heat exchangers due to catalyst fines in a recirculation loop. We engineered a custom metal mesh filter, specifically an inline stainless steel mesh filter with a 25-micron rating, designed for the high-temperature (250°C) and corrosive chemical environment. Post-implementation, the plant reported a 70% reduction in heat exchanger maintenance downtime and an estimated annual savings of $150,000 in operational costs, proving the long-term value of a reliable filtering mesh.

For a pharmaceutical client requiring ultra-pure water for API synthesis, existing filters failed to consistently meet sub-micron particulate removal standards. We provided a series of advanced fine mesh filter cartridges, leveraging specific woven Dutch weave stainless steel mesh. These filters achieved a consistent 5-micron absolute rating, dramatically reducing impurity levels and increasing batch purity by 8%, directly impacting product quality and regulatory compliance.

A municipal wastewater treatment facility needed a robust pre-filtration solution for large debris and coarse solids prior to primary clarifiers. We supplied durable galvanised mesh filters in large cylindrical formats. These units effectively captured debris, reducing the load on downstream equipment and extending the lifespan of finer filtration stages by 40%. The robust filter metal mesh proved its resilience in a demanding environment.

These examples underscore our capability to deliver tailored solutions that address specific operational challenges and yield measurable improvements. The integrity of our brass mesh filter and other metal mesh filters directly translates into tangible benefits for our clients.

The performance of Woven Wire Mesh Filter Tubes and Cartridges can be precisely quantified through various technical indicators. These metrics are critical for assessing efficiency, capacity, and suitability for specific applications. Understanding these parameters helps in selecting the right filtering mesh for your needs and predicting its operational lifespan. The data presented below represents typical performance ranges for our high-quality filtration products, demonstrating their robust capabilities across different scenarios. This data can be graphically represented as various charts to visualize performance trends and comparisons.

Indicator | Typical Value Range | Notes for Application |

Filtration Accuracy (Micron Rating) | 1 µm to 2000 µm | Determines particle removal size; fine mesh filter applications target lower µm values. |

Operating Pressure | Up to 30 MPa (4350 psi) | Maximum pressure differential the filter can withstand without deformation. Robust filter steel mesh excels here. |

Operating Temperature | -200°C to +800°C | Material dependent (e.g., brass mesh filter has lower temp limit than stainless steel). |

Flow Rate (per unit area) | Varies widely by mesh type (e.g., 5-500 L/min/m²) | Influenced by porosity and filter area; higher for efficient inline stainless steel mesh filter systems. |

Dirt Holding Capacity | Up to 15 kg/m³ | Volume of contaminants a filter can retain before pressure drop increases significantly. |

Pressure Drop (Initial) | Typically < 0.05 MPa | Indicates energy efficiency; lower is better for filtering mesh. |

This table provides a snapshot of our product capabilities. For instance, the high operating temperature range of filter steel mesh makes it indispensable in processes like high-temperature gas filtration, while the low pressure drop ensures energy-efficient operation. Our commitment to delivering certified products that meet or exceed these critical performance indicators is unwavering. For specific requirements, our engineering team can provide detailed performance curves and simulations for custom metal mesh filters.

Q1: What is the typical lifespan of a Woven Wire Mesh Filter Tube?

A1: The lifespan varies significantly based on operating conditions (temperature, pressure, contaminant load), media corrosiveness, and cleaning frequency. High-quality filter steel mesh can last several years with proper maintenance, while a brass mesh filter in less demanding applications might have a similar lifespan. Regular cleaning and suitable material selection (e.g., 316L for corrosive environments) are key determinants.

Q2: Can these filters be cleaned and reused?

A2: Yes, a significant advantage of woven metal mesh filters, especially those made from stainless steel, is their reusability. They can typically be cleaned through backwashing, ultrasonic cleaning, or chemical rinsing, depending on the type of contaminant and mesh material. This significantly reduces operational costs compared to disposable cartridges, particularly for fine mesh filter applications.

Q3: How do I specify a custom metal mesh filter for my application?

A3: To specify a custom metal mesh filter, you'll need to provide details on the fluid/gas properties, operating temperature and pressure, desired filtration accuracy (micron rating), flow rate, and the physical dimensions required. Our engineering team can assist you in selecting the optimal material (e.g., inline stainless steel mesh filter vs. galvanised mesh filters) and design configuration.

Q4: What is the difference between absolute and nominal micron ratings for a filtering mesh?

A4: An absolute micron rating indicates that the filter can capture 99.9% of particles at or above a specified micron size. A nominal rating suggests that the filter can capture a significant percentage (e.g., 90%) of particles at or above a given micron size. For critical applications, an absolute rating is preferred, especially for fine mesh filter requirements.

Q5: Are your filter metal mesh products compliant with international standards?

A5: Yes, our manufacturing processes and products are often compliant with international standards such as ISO 9001 for quality management. We also adhere to material specifications and testing procedures laid out by organizations like ASTM and ANSI. Specific industry certifications (e.g., for food-grade filter steel mesh) can be provided upon request.

Q6: What is your typical lead time for custom filter orders?

A6: Lead times for custom metal mesh filters can vary based on complexity, material availability, and order volume. Generally, custom orders are completed within 3-6 weeks after design finalization. Standard inline stainless steel mesh filter or galvanised mesh filters may have shorter lead times, typically 2-4 weeks. We prioritize clear communication regarding production schedules.

Q7: Do you offer technical support for installation and troubleshooting?

A7: Absolutely. Our dedicated technical support team is available to assist with installation guidelines, operational optimization, and troubleshooting any issues that may arise with our filtering mesh products. We aim to ensure seamless integration and long-term satisfactory performance for all our clients.

As a professional SEO content strategist and technical copywriter specializing in B2B, we understand the critical importance of reliable filtration solutions. Our Woven Wire Mesh Filter Tubes and Cartridges, encompassing options like brass mesh filter, custom metal mesh filters, filter metal mesh, filter steel mesh, filtering mesh, fine mesh filter, galvanised mesh filters, and inline stainless steel mesh filter, are engineered to deliver unparalleled performance and longevity. We stand by our products with a comprehensive quality assurance program, including a standard 2-year warranty on all manufactured filter elements and robust customer support available 24/7. Our partnerships with leading engineering, procurement, and construction (EPC) firms, alongside our ISO 9001 certification, underscore our authoritative position in the industry. By choosing our filtration solutions, you invest in operational excellence, enhanced system protection, and a commitment to sustainable industrial practices.

1. American Society for Testing and Materials (ASTM) Standards for Metal Wire and Mesh.

2. International Organization for Standardization (ISO) 9001:2015 Quality Management Systems.

3. Filtration & Separation Journal, Elsevier, various technical articles on industrial mesh filtration.

4. National Association of Corrosion Engineers (NACE) International publications on material selection and corrosion control.

5. Fluid Power World technical reports on hydraulic and lubrication filtration.

Contact Information

Quick Link

Product

Copyright © 2025 Anping Tengde Metal Wire Mesh Products Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Please leave us a message and we will get back to you shortly.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.