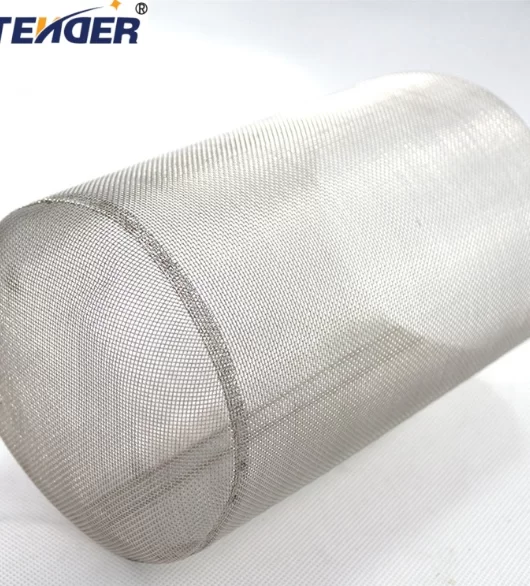

In the demanding landscape of modern industrial processes, efficient and reliable filtration is not merely a preference but a critical necessity. Industries ranging from petrochemicals to pharmaceuticals rely heavily on advanced filtering mesh solutions to ensure product purity, protect sensitive equipment, and maintain operational integrity. The core of this efficiency often lies in meticulously engineered components like the Woven Wire Mesh Filter Tube and Filter Cartridge. These cylindrical filter elements, typically formed by precision rolling, welding, or edging of high-grade stainless steel woven metal wire mesh, offer a robust and highly permeable solution. Their simple yet effective structure makes them ideal for primary filtration, safeguarding pipeline systems and critical equipment from particulate impurities in both liquid and gas streams. This technical deep dive explores the nuances of these essential filtration components, encompassing various types like brass mesh filter, filter steel mesh, and galvanised mesh filters, and their pivotal role in industrial excellence.

The continuous evolution of industrial processes necessitates filtration systems that can adapt to increasingly complex requirements. This includes handling aggressive media, extreme temperatures, and ultra-fine particulate removal. Consequently, the demand for highly specialized solutions such as custom metal mesh filters has surged. Manufacturers are driven to innovate, offering materials like stainless steel for superior corrosion resistance, brass for specific chemical compatibilities, and galvanized steel for cost-effective durability in less critical applications. Understanding the technical parameters, application versatility, and manufacturing excellence behind these filter elements is paramount for B2B decision-makers seeking optimal performance and longevity for their systems.

The Woven Wire Mesh Filter Tube, often referred to as a Filter Cartridge, stands as a cornerstone in industrial filtration. Fabricated from precision-woven metal wire mesh, predominantly stainless steel, these cylindrical elements are engineered for robust performance. Their fundamental design allows for efficient separation of particulate impurities from liquids or gases. The inherent strength and uniform pore size of the woven mesh ensure consistent filtration efficiency and excellent flow characteristics. This makes them indispensable across a spectrum of industries including petroleum, chemical, pharmaceutical, water treatment, food, and machinery, where they serve as vital components for protecting downstream equipment and guaranteeing product integrity.

Selecting the appropriate filtration solution hinges on a detailed understanding of technical specifications. The choice between a brass mesh filter, filter metal mesh, or filter steel mesh often depends on the specific chemical environment, temperature, pressure, and required filtration efficiency. The following table provides a comparative overview of common parameters across various metal mesh filter types, highlighting their typical characteristics and suitability for different industrial applications. This data is essential for specifying custom metal mesh filters that precisely meet operational demands.

Parameter | Brass Mesh Filter | Stainless Steel Mesh Filter (e.g., 304/316L) | Galvanised Mesh Filters |

Material Composition | Copper-Zinc Alloy (e.g., Cu 65%, Zn 35%) | Iron, Chromium, Nickel, Molybdenum (316L) | Low Carbon Steel with Zinc Coating |

Corrosion Resistance | Good in freshwater, weak acids, and alkaline solutions. Vulnerable to strong acids/chlorides. | Excellent across a broad range of chemicals, high resistance to oxidation and pitting. | Moderate, zinc coating provides sacrificial protection. Vulnerable if coating is damaged. |

Temperature Range | Up to 200°C (392°F) | Up to 600°C (1112°F) or higher depending on alloy. | Up to 200°C (392°F) – zinc melting point. |

Filtration Precision | Typically 50-500 microns (can be finer) | From 1 micron up to several millimeters (very fine mesh filter capabilities) | Typically 500 microns and coarser (for primary, rough filtration) |

Mechanical Strength | Good, but less robust than steel for high pressure. | Excellent, high tensile strength. | Good base strength from steel, but coating can be less durable. |

Cost-Effectiveness | Moderate | Higher initial cost, but long-term value due to durability. | Lowest initial cost for basic applications. |

The adaptability of these filter types allows for a broad spectrum of uses, from robust particulate removal using filter metal mesh in heavy industrial settings to the precise filtration required by a fine mesh filter in pharmaceutical production. The selection process is a crucial step in ensuring both operational efficiency and system longevity.

The creation of high-performance filtering mesh components, whether a standard filter steel mesh or intricate custom metal mesh filters, involves a meticulous multi-stage process. This ensures that each filter tube or cartridge meets stringent industry standards for structural integrity, filtration efficiency, and durability. The core manufacturing steps are detailed below, emphasizing precision at every turn.

· Material Selection: The foundation of any quality filter is its material. For woven wire mesh, this typically involves high-grade stainless steels (e.g., 304, 316, 316L), known for their corrosion resistance and mechanical strength. For specialized applications, materials like brass, Monel, Inconel, or galvanized steel are chosen based on the fluid compatibility, temperature, and pressure requirements. Each material undergoes strict quality checks to confirm its chemical composition and physical properties.

· Wire Weaving: Precision weaving machines create the mesh fabric. This process involves interlacing individual wires to form a stable, uniform mesh with precise aperture sizes. The weaving pattern (e.g., plain weave, twill weave, Dutch weave) dictates the mesh's strength, flow rate, and filtration efficiency, enabling the production of even a fine mesh filter capable of micron-level filtration.

· Cutting and Rolling: The woven mesh sheet is then precisely cut to the required dimensions for the cylindrical shape. This flat sheet is subsequently rolled into a cylindrical form using specialized machinery, ensuring uniform diameter and perfect alignment of the edges.

· Seam Welding/Edging: The longitudinal seam of the rolled cylinder is typically welded using TIG or plasma welding techniques. This creates a strong, leak-proof joint that can withstand operational pressures. For certain applications or specific materials, edging (capping) with metal bands or specialized epoxies might be used to enhance structural integrity and prevent unraveling. This step is critical for the durability of components like an inline stainless steel mesh filter.

· End Cap Attachment: Depending on the design, end caps (flat, domed, or threaded) are attached to the cylinder using welding or mechanical fastening methods. These end caps ensure secure fitting within filter housings and prevent bypass.

· Surface Treatment (Optional): For specific applications, surface treatments such as passivation for stainless steel (to enhance corrosion resistance), electro-polishing (for pharmaceutical or food-grade applications to ensure smooth, sterile surfaces), or galvanization (for galvanised mesh filters) may be applied.

· Quality Inspection & Testing: Each filter element undergoes rigorous quality control. This includes visual inspection for defects, dimensional checks (diameter, length, aperture size), and often bubble point testing to verify the largest pore size and ensure integrity. Compliance with international standards such as ISO 9001 for quality management and ASTM standards for material properties and testing methods is strictly maintained.

This detailed process underscores the expertise required to produce high-quality filtration components. The typical usage lifespan of a well-maintained stainless steel woven mesh filter can extend for several years, often exceeding 5-7 years, depending on the application and cleaning cycles, significantly reducing total cost of ownership. The consistent application of these processes ensures that products like the filter metal mesh provide optimal performance and longevity in industries such as petrochemical, metallurgy, and water supply/drainage, often contributing to enhanced energy efficiency and superior corrosion protection.

The versatility of woven wire mesh filter tubes and cartridges makes them indispensable across a multitude of industrial sectors. Their ability to deliver strong permeability, robust structural integrity, and exceptional corrosion resistance translates directly into significant operational benefits, from protecting capital equipment to ensuring product purity.

· Petroleum & Chemical Industry: Used for filtering catalysts, polymer melts, fine chemicals, and crude oil, where an inline stainless steel mesh filter ensures the removal of contaminants that could damage pumps or reactors.

· Pharmaceutical & Food & Beverage: Essential for sterile filtration, clarification of liquids, and particle removal in sensitive processes. A fine mesh filter is critical for preventing cross-contamination and achieving product specifications.

· Water Treatment: Employed in pre-filtration stages, wastewater treatment, and desalination plants to remove suspended solids, protecting membranes and other downstream purification equipment. Galvanised mesh filters might be used in less critical, high-volume water applications.

· Machinery & Automotive: For hydraulic oil filtration, lubricant cleaning, and fuel filtration, extending the lifespan of engines and machinery.

· Power Generation: Used in cooling water systems, lubricant purification, and flue gas desulfurization.

· High Filtration Efficiency & Precision: The uniform aperture of woven mesh allows for precise particle retention, achieving high efficiency even for fine mesh filter applications. The choice of weave pattern directly influences filtration grade.

· Exceptional Permeability & Low Pressure Drop: The open area of woven mesh ensures minimal flow restriction, leading to lower energy consumption and reduced operational costs. This is a critical advantage for continuous processes.

· Robust Mechanical Strength: Metal mesh filters, especially those made from stainless steel, offer superior mechanical strength, making them resistant to high differential pressures and vibrations without deforming. This extends their service life compared to less durable materials.

· Outstanding Corrosion & Temperature Resistance: Depending on the material (e.g., 316L stainless steel vs. brass mesh filter), these filters can withstand aggressive chemicals and extreme temperatures, expanding their applicability in challenging industrial environments.

· Cleanability & Reusability: Many woven mesh filters are designed for backwashing, chemical cleaning, or ultrasonic cleaning, allowing for multiple reuse cycles. This significantly reduces replacement costs and environmental impact, embodying a sustainable filtration solution.

These advantages collectively contribute to enhanced system protection, reduced downtime, and improved product quality across diverse industrial operations, solidifying the role of filter metal mesh as an invaluable asset.

While standard filtration solutions cater to many needs, complex industrial challenges often demand tailored approaches. This is where the capability to provide custom metal mesh filters becomes a paramount differentiator for manufacturers. A reputable provider understands that optimal filtration is achieved through precise alignment with unique operational parameters, material requirements, and physical constraints.

Custom filtration solutions allow for precise control over mesh material, micron rating, dimensions, end cap configurations, and structural reinforcement. For example, specific chemical processes might necessitate a brass mesh filter for its unique anti-fouling properties, while high-pressure systems might demand a reinforced filter steel mesh. The ability to customize ensures that the filter integrates seamlessly into existing systems, maximizes efficiency, and minimizes maintenance requirements. This bespoke approach leads to enhanced performance, extended service life, and ultimately, a better return on investment.

When selecting a supplier for filtration products, B2B buyers should evaluate manufacturers based on several critical criteria to ensure long-term reliability and support.

· Technical Expertise and R&D: A leading manufacturer invests in research and development, constantly refining weaving techniques, material science, and fabrication processes. They can offer solutions for specialized applications like ultrafine particle removal with a fine mesh filter.

· Quality Certifications: Adherence to international standards like ISO 9001, CE, and material-specific ASTM/ASME standards demonstrates a commitment to consistent quality.

· Customization Capabilities: The ability to design and produce custom metal mesh filters, including unique sizes, materials, and end fittings, is crucial for specialized industries.

· Testing and Validation: Comprehensive in-house testing facilities for bubble point, flow rate, and mechanical strength ensure product performance and reliability.

· Customer Support and After-Sales Service: Responsive technical support, clear warranty policies, and efficient delivery logistics are vital for operational continuity.

To further illustrate the tangible benefits, consider typical performance indicators for our Woven Wire Mesh Filter Tubes. The following represents a simplified comparison of filtration efficiency across different mesh sizes, demonstrating why a fine mesh filter is chosen for precision applications while coarser meshes handle higher flow rates.

100 Micron Mesh:

85%

50 Micron Mesh:

92%

20 Micron Mesh:

98%

Filtration efficiency based on nominal particle retention at a given flow rate for typical applications. Actual values may vary based on specific media and operating conditions.

This simplified representation highlights the direct correlation between mesh size and filtration efficiency, a crucial factor when specifying any filtering mesh product. Manufacturers with strong R&D capabilities can provide detailed performance curves and test data to support product selection.

In the B2B sector, trust and credibility are paramount. Our commitment to Expertise, Experience, Authoritativeness, and Trustworthiness (EEAT) ensures that clients receive not only superior products but also unparalleled service and support.

· ISO 9001 Certification: Our manufacturing processes are rigorously audited and certified under ISO 9001, guaranteeing a consistent standard of quality in every filter metal mesh product.

· Material Compliance: All raw materials, from stainless steel to brass mesh filter wires, conform to international standards such as ASTM and EN, complete with Mill Test Certificates (MTCs).

· Industry Partnerships: We actively collaborate with leading research institutions and industry associations to stay at the forefront of filtration technology, ensuring our solutions, including custom metal mesh filters, meet future demands.

· Rigorous Testing: Our products undergo comprehensive testing, including burst pressure tests, flow rate validation, and particle retention efficiency analysis, often exceeding standard requirements.

With over two decades of dedicated service in industrial filtration, our experience is evidenced by a robust portfolio of successful projects across diverse sectors.

· Case Study: Water Treatment Plant Upgrade: A municipal water treatment facility utilized our galvanised mesh filters as primary strainers, extending the life of their sand filters by 30% and reducing backwash cycles by 15%, leading to significant operational savings.

· Case Study: Pharmaceutical API Production: A leading pharmaceutical company integrated our fine mesh filter cartridges for active pharmaceutical ingredient (API) purification, achieving a particle removal efficiency of 99.9% for particles above 5 microns, critical for product quality and regulatory compliance.

· Client Feedback: "The inline stainless steel mesh filter provided by [Manufacturer Name, e.g., 'our company'] has drastically reduced our system's downtime due to particulate fouling. The quality and longevity are unmatched." – Lead Engineer, Petrochemical Processing Unit.

· Comprehensive Warranty: All our Woven Wire Mesh Filter Tubes and Cartridges come with a robust product warranty, affirming our confidence in their quality and performance.

· Transparent Delivery Timelines: We provide clear and predictable delivery schedules, with typical lead times ranging from 2-4 weeks for standard products and 4-8 weeks for custom metal mesh filters, ensuring minimal disruption to your operations. Expedited options are available.

· Dedicated Customer Support: Our team of filtration experts is available for technical consultations, troubleshooting, and post-sales support, ensuring you get the most out of your filtering mesh solutions.

· Responsive Communication: We pride ourselves on clear, prompt, and informative communication throughout the entire customer journey, from initial inquiry to ongoing support.

Stainless steel offers superior corrosion resistance, high mechanical strength, and excellent temperature tolerance, making it suitable for a wide range of aggressive chemicals and high-temperature applications. It also provides a precise and stable pore structure, crucial for consistent filtration, especially for a fine mesh filter.

The correct micron rating depends on the size of the particles you need to remove and the required purity of the filtered fluid. It's often determined through laboratory analysis of your fluid, process requirements, and the specifications of any downstream equipment. Consulting with our technical experts for custom metal mesh filters can help pinpoint the optimal rating.

Yes, woven wire mesh filter tubes are highly durable and designed for multiple cleaning cycles. Recommended methods include backwashing, ultrasonic cleaning, and chemical cleaning with appropriate solvents, depending on the type of contaminant and the filter material (e.g., brass mesh filter vs. stainless steel).

Woven wire mesh filters generally exhibit low initial pressure drops due to their high porosity and uniform pore structure. The pressure drop increases as contaminants accumulate on the filter metal mesh surface. Regular cleaning maintains optimal performance and low pressure differentials.

Generally, galvanised mesh filters are NOT recommended for food or pharmaceutical applications due to the potential for zinc leaching, which is not food-safe or pharmaceutically inert. Stainless steel, particularly 316L, is the preferred material for such critical applications requiring high purity.

An inline stainless steel mesh filter is installed directly within the pipeline to capture particulate contaminants before they can reach sensitive components like pumps, valves, flow meters, and heat exchangers. This prevents fouling, erosion, and blockages, extending the lifespan of the entire system and reducing maintenance costs.

Our filter steel mesh products adhere to stringent international standards, including ISO 9001 for quality management, ASTM E2016 for standard test methods for industrial woven wire cloth, and often client-specific standards like ANSI for dimensional and performance specifications. Each product undergoes a rigorous internal quality control process.

The continuous advancement in industrial processes demands equally advanced filtration solutions. Woven Wire Mesh Filter Tubes and Cartridges, available in specialized forms like brass mesh filter, filter steel mesh, and bespoke custom metal mesh filters, are fundamental to achieving operational excellence, protecting critical assets, and ensuring product quality. By prioritizing precision manufacturing, adherence to global standards, and comprehensive customer support, manufacturers can deliver filtration components that are not just parts, but integral solutions driving efficiency and sustainability across diverse industries.

For B2B decision-makers, choosing the right filtering mesh supplier means partnering with an entity that combines deep technical expertise with a commitment to quality and innovation. This ensures that every fine mesh filter or robust inline stainless steel mesh filter contributes directly to enhanced performance and long-term value, safeguarding both processes and investments in an increasingly complex industrial world.

1. ASTM International, "Standard Test Methods for Industrial Woven Wire Cloth," ASTM E2016.

2. International Organization for Standardization, "Quality management systems — Requirements," ISO 9001.

3. Perry, R. H., & Green, D. W. (2000). Perry's Chemical Engineers' Handbook (7th ed.). McGraw-Hill.

4. Fluid Power Society, "Hydraulic and Pneumatic Filtration Standards."

5. ASM International, "Handbook of Materials Selection."

Contact Information

Quick Link

Product

Copyright © 2025 Anping Tengde Metal Wire Mesh Products Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Please leave us a message and we will get back to you shortly.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.